Safety First When Working with Abrasives

Protecting your team is protecting your business. OSHA’s PPE standards for abrasive tool operators are critical for compliance, safety, and operational continuity. This guide will help you understand and apply those standards effectively.

II. Understanding OSHA's Framework for PPE

OSHA's requirements for PPE are part of a broader strategy for controlling workplace hazards. It's essential for both employers and employees to understand this framework to ensure effective protection.

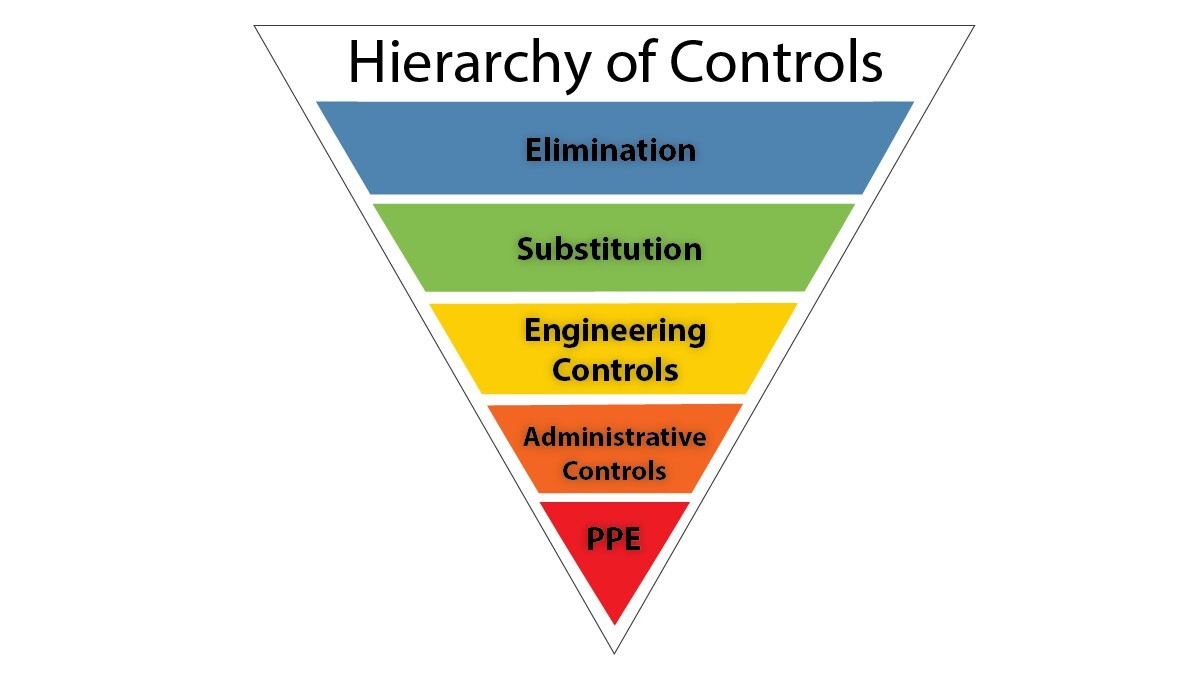

A. The Hierarchy of Controls: PPE as the Last Line of Defense

Working with abrasive tools—grinders, sanders, cut-off wheels, wire brushes, and more—poses risks like flying debris, dust, sparks, vibration, and high noise levels. OSHA mandates a layered safety strategy known as the Hierarchy of Controls, which outlines a step-by-step method to reduce workplace hazards in order of effectiveness:

- Engineering controls: These are the most effective and aim to remove or isolate the hazard at its source. Examples include dust collection systems, tool guards, sound-dampening enclosures, or replacing hazardous materials with safer alternatives.

- Administrative controls: These involve changes in work policies and practices—like limiting the time workers spend on a high-risk task, designating restricted areas, or providing safety training to workers.

- Personal Protective Equipment (PPE): As the last line of defense, PPE protects workers when the first two levels aren’t enough. Equipment like safety glasses, gloves, respirators, and hearing protection can significantly reduce the risk of injury—but only when selected, fitted, and used properly.

Employers should prioritize engineering and administrative controls whenever possible and treat PPE as a supplemental safeguard—not a substitute for eliminating hazards.

B. Employer Responsibilities: The Foundation of Safety

OSHA mandates that employers create and uphold a safe work environment, which includes a comprehensive PPE program. This involves more than just providing equipment; it requires a systematic approach to ensure compliance. Employers are responsible for several key duties in this regard.

- Hazard Assessment: Employers are required to conduct and document a workplace hazard assessment to determine necessary PPE for protecting employees from potential eye, face, head, extremity, torso, and respiratory hazards. This assessment, including identified hazards and certification details, is crucial for all PPE decisions..

- PPE Selection and Provision: Employers must choose and communicate appropriate, properly fitting PPE based on hazard assessments to protect employees..

- Payment for PPE: Employers generally must provide and pay for necessary PPE for employees, with limited exceptions. Employers are responsible for replacements unless the employee lost or intentionally damaged the PPE. Employees cannot be required to provide their own PPE outside of these specific exceptions..

- Training: Employers must train employees on when, what, and how to use required PPE, its limitations, care, and disposal. Employees must understand and correctly use PPE before work. Retraining is needed for changes or inadequate use. Employers must certify training in writing..

- Maintenance and Replacement: Maintain all PPE in sanitary and reliable condition. Immediately replace defective or damaged PPE. Reused PPE must be properly cleaned and disinfected before reissuance..

PPE Categories for Abrasive Operations

Abrasive operations often necessitate several types of personal protective equipment (PPE) due to common hazards. However, a workplace hazard assessment is always required to determine the specific PPE needs..

A. Eye and Face Protection (OSHA 29 CFR 1910.133 / 1926.102)

- Hazard: Abrasive tasks almost always generate flying particles, debris, and sparks that pose a significant risk to the eyes and face.

- Requirement: OSHA requires employers to ensure employees use appropriate eye or face protection whenever exposed to these hazards. For abrasive wheel use specifically, eye protection is mandatory for all users. The protection must meet the requirements of the American National Standards Institute (ANSI) Z87.1 standard, "Occupational and Educational Personal Eye and Face Protection Devices," or be demonstrated by the employer to be equally effective. If a hazard from flying objects exists, the eye protection must provide side protection, either integrated or via detachable side shields. Employees requiring prescription lenses must wear protection that incorporates the prescription or can be worn comfortably over their regular glasses without compromising fit or function.

B. Hand Protection (OSHA 29 CFR 1910.138)

- Hazard: Abrasive tool operators risk cuts, lacerations, abrasions, punctures from tools, workpieces, or debris, as hands are close to the operation point. Thermal burns from friction are also a risk during prolonged use. Chemical burns or absorption may occur with solvents or cleaners..

- Requirement: Employers are required to provide and mandate appropriate hand protection based on task evaluation, conditions, duration, and identified hazards, as a single glove type is often insufficient for all abrasive tasks.

C. Respiratory Protection (OSHA 29 CFR 1910.134)

- Hazard: Abrasive operations create hazardous airborne dust from the abrasive material, the workpiece, or removed coatings. This dust can include crystalline silica (causing silicosis), wood dust (linked to respiratory issues and cancer), and toxic metal dusts and fumes. Polishing and buffing also generate dust..

- Requirement: OSHA requires the use of respirators when engineering controls (like ventilation) and administrative controls are not feasible or do not reduce employee exposures to airborne contaminants below the applicable OSHA Permissible Exposure Limits (PELs). If respirators are deemed necessary, the employer must establish and implement a comprehensive written respiratory protection program that complies with 29 CFR 1910.134. This program requirement underscores that providing respiratory protection involves more than simply issuing masks. Even if respirator use is voluntary, the employer must still ensure the employee is medically able to use the respirator, that it doesn't create a hazard, and that it is cleaned, stored, and maintained properly.

D. Hearing Protection (OSHA 29 CFR 1910.95)

- Hazard: Grinding, cutting, blasting, and other abrasive processes can generate high noise levels, potentially leading to permanent hearing loss over time.

- Requirement: OSHA's Occupational Noise Exposure standard (1910.95) requires employers to implement a Hearing Conservation Program (HCP) if employees are exposed to noise levels equaling or exceeding an 8-hour time-weighted average (TWA) of 85 decibels on the A-scale (dBA). This 85 dBA level is known as the Action Level. While the Permissible Exposure Limit (PEL) is a TWA of 90 dBA, the requirement for an HCP starts at the lower 85 dBA threshold. Hearing protectors must be made available to all employees exposed at or above the 85 dBA Action Level. Hearing protector use is mandatory when exposures exceed the 90 dBA PEL, or for any employee exposed above 85 dBA who has not yet received a baseline audiogram or has experienced an STS.

E. Foot, Head, and Body Protection

- Foot Protection (OSHA 29 CFR 1910.136): Required where there is a danger of foot injuries from falling or rolling objects, objects piercing the sole, or electrical hazards.

- Head Protection (OSHA 29 CFR 1910.135): Required when working in areas with potential for head injury from falling objects or bumping against fixed objects like pipes or beams. Also required near exposed electrical conductors. Hard hats compliant with ANSI Z89.1 are typically used. Abrasive blasting operations require specialized helmets that also integrate respiratory protection and protect the head, neck, and shoulders.

- Body Protection: Protection for the torso, arms, and legs is necessary when hazards like intense heat, splashes of hot metal (possible in some heavy grinding/cutting scenarios), impacts, cuts, hazardous chemicals, or excessive sparks exist. Leather aprons, jackets, or coveralls provide good protection against sparks and moderate heat. Full body suits might be needed for extensive abrasive blasting or chemical exposures.

PPE Guidance for Specific Abrasive Tools & Operations

To understand OSHA's PPE requirements, it's helpful to connect general guidelines to the specific abrasive tools and products used regularly. The following sections offer guidance for common abrasive operations, referencing relevant Empire Abrasives products. Please note that this information is general; always conduct a site-specific hazard assessment.

A. Grinding & Cutting (Bonded Wheels, Cut-Off Wheels, Chop Saw Wheels, Flap Discs, Grinding Wheels)

- Primary Hazards: High-speed abrasive discs pose significant risks to operators, including flying particles, wheel breakage, sparks, high noise, heat, and contact with the rotating wheel during material removal..

- Key Standards: OSHA 29 CFR 1910.215 (Abrasive wheel machinery - General Industry) and 1926.303 (Abrasive wheels and tools - Construction). Additionally, the general PPE standards in Subpart I (1910.133 Eye/Face, 1910.138 Hand, 1910.134 Respiratory, 1910.95 Hearing) apply.

- Required/Recommended PPE:

- Eye/Face: OSHA recommends a face shield over ANSI Z87.1 safety glasses or goggles for abrasive tool operators due to the high risk of flying particles and wheel fracture. Maximum protection is crucial...

- Hearing: Noise levels often exceed the 85 dBA Action Level and potentially the 90 dBA PEL. A Hearing Conservation Program and mandatory use of hearing protectors are likely required per 1910.95.

- Hand: Durable gloves, such as leather, are needed to protect against sparks, heat, sharp edges on the workpiece, and potential contact.

- Respiratory: Dust generation depends on the material being ground and the duration of work. Exposure monitoring should determine if respirators are needed according to 1910.134 requirements.

- Body/Foot: Leather aprons or jackets are advisable for protection from sparks, especially during heavy grinding. Safety shoes are recommended due to potentially heavy tools and materials.

B. Sanding (Belts, Discs - Hook & Loop, PSA, Quick Change, Sheets, Rolls, Drums, Flap Wheels, Cartridge Rolls, Spiral Bands, Cross Pads)

- Primary Hazards: The main hazard is airborne dust, which can be composed of wood, metal, paint/coatings, fillers, or the abrasive material itself. Flying particles, contact with moving belts/discs/drums (especially nip points on belt sanders), noise, and heat generated by friction are also concerns.

- Key Standards: General PPE standards (Subpart I: 1910.133 Eye, 1910.138 Hand, 1910.134 Respiratory, 1910.95 Hearing) and General Machine Guarding (1910.212) apply.

- Required/Recommended PPE:

- Eye: ANSI Z87.1 safety glasses are the minimum requirement. Goggles may offer better protection against fine dust.

- Respiratory: The potential for inhaling harmful dust is high when using these types of abrasives. If PELs are exceeded, or if significant visible dust is generated, a NIOSH-certified respirator (e.g., N95 filtering facepiece or better, depending on contaminant and concentration) is required under a full 1910.134 program.

- Hand: Gloves appropriate for the material being handled, offering protection from abrasion and potential heat, are needed. Caution is advised with gloves near unguarded nip points on belt sanders, as they can be caught.

- Hearing: Noise levels should be evaluated, and hearing protection used according to 1910.95 if the 85 dBA TWA Action Level is reached.

C. Surface Conditioning, Polishing & Buffing (Non-Woven Belts/Discs/Pads, Buffing Wheels, Compounds)

- Primary Hazards: Hazards include airborne dust and fibers from the non-woven material or buffing wheel, residue from polishing compounds, eye irritation, contact with rotating parts, potential entanglement on exposed spindles, and noise. The risk of catastrophic wheel failure is significantly lower than with bonded abrasive wheels.

- Key Standards: OSHA explicitly classifies these items (like 3M Scotch-Brite nonwoven products) as polishing and buffing wheels, not abrasive grinding wheels. Therefore, the specific guarding requirements of 1910.215 do not apply. Instead, relevant standards include 1910.94(b) (Ventilation for polishing and buffing operations) , the general PPE standards in Subpart I (1910.133 Eye, 1910.138 Hand, 1910.134 Respiratory, 1910.95 Hearing) , and 1910.212 (General Machine Guarding) for hazards like entanglement.

- Required/Recommended PPE:

- Eye: ANSI Z87.1 safety glasses are necessary to protect against dust and debris.

- Hand: Gloves suitable for handling the workpiece and potentially messy compounds are recommended.

- Respiratory: Dust from the wheel/pad material and fumes or dust from polishing compounds can be inhaled. Exposure should be evaluated, and respirators used if PELs are exceeded, following 1910.134 requirements. Effective local exhaust ventilation, as outlined in 1910.94(b), is the preferred control method.

- Hearing: Polishing machines can generate noise; evaluate levels and provide protection per 1910.95 if necessary.

- Body: An apron may be useful to protect clothing from compounds and debris.

D. Wire Wheels & Brushes (Cup, End, Handheld, Wheel)

- Primary Hazards: Operating wire abrasive tools presents several key hazards. Notably, the high-speed rotation of wire wheels can cause filaments to detach and become dangerous projectiles, leading to serious eye injuries or skin punctures. Direct contact with the rotating wheel can also result in lacerations and entanglement. Additionally, operators may be exposed to elevated noise levels.

- Key Standards: Similar to polishing wheels, wire wheels are not considered abrasive wheels under 1910.215. Hazards must be addressed under 1910.212 (General Machine Guarding) and the general PPE standards in Subpart I (1910.133 Eye/Face, 1910.138 Hand, 1910.95 Hearing).

- Required/Recommended PPE:

- Eye/Face: Due to the high risk of penetrating injuries from flying wires, maximum protection is crucial. A full face shield worn over ANSI Z87.1 safety glasses or goggles is strongly recommended. Standard safety glasses alone may not be sufficient.

- Hand: Durable gloves, such as leather, are essential to protect against wire punctures, cuts, and abrasion.

- Hearing: Wire brushing can be noisy; evaluate levels and implement 1910.95 requirements if the 85 dBA Action Level is reached.

- Body: A leather apron or durable jacket is advisable to protect the torso and arms from flying wires.

E. Other Tools (Tungsten Carbide Burrs, Reciprocating/Hole Saws, Hand Files/Pads, Flooring Abrasives)

PPE requirements for these tools are determined by applying general OSHA principles based on the specific hazards identified in the workplace assessment:

- Tungsten Carbide Burrs: Used in die grinders, these create hazards from high-speed flying chips and potential cuts. ANSI Z87.1 eye protection is essential. Gloves are needed for handling.

- Reciprocating Saws and Hole Saws: Hazards include contact with the moving blade and flying chips or material fragments. ANSI Z87.1 eye protection is required. Gloves are needed for handling materials and the tool. Blades must be appropriately guarded, and some saws require constant pressure controls.

- Hand Files and Hand Pads: Primary hazards are cuts and abrasions to the hands. Gloves are the main PPE requirement. If significant dust is generated (depending on the material being filed or sanded), eye protection and potentially a dust mask may be needed.

- Flooring Abrasives (Rolls, Discs, Belts, Screens, Pads): Used on large floor sanding or buffing machines, these operations generate high levels of dust (wood, finishes, concrete, abrasive material) and significant noise. Respiratory protection is critical and likely requires assessment under 1910.134. Eye protection and hearing protection under 1910.95 are also essential. Gloves are needed for handling abrasives and the machine. Guarding of rotating parts falls under 1910.212.

Table: PPE Quick Reference for Abrasive Operations

The following table provides a general summary. Note: This is not exhaustive and does not replace a site-specific hazard assessment and review of applicable OSHA standards. PPE selection must be based on identified hazards, exposure levels, and specific task requirements.

|

Abrasive Tool/Operation |

Primary Hazards |

Key OSHA Standard(s) |

Recommended/Required PPE |

|

Grinding & Cutting (Bonded Wheels, Cut-Off Wheels, Chop Saw Wheels, Flap Discs, Grinding Wheels) |

Flying Particles, Wheel Breakage, Sparks, Noise, Heat, Rotating Part Contact |

1910.215 / 1926.303 (Wheels); 1910.133 (Eye); 1910.138 (Hand); 1910.134 (Resp); 1910.95 (Hearing) |

Eye/Face: Glasses + Face Shield; Hearing: Likely Required; Hand: Leather Gloves; Respiratory: Evaluate Dust; Body/Foot: Apron/Safety Shoes Recommended |

|

Sanding (Belts, Discs, Sheets, Rolls, Drums, Flap Wheels, Cartridge Rolls, Spiral Bands, Cross Pads) |

Airborne Dust (Wood, Metal, Coatings, etc.), Flying Particles, Rotating/Nip Points, Noise, Heat |

1910.133 (Eye); 1910.138 (Hand); 1910.134 (Resp); 1910.95 (Hearing); 1910.212 (Guarding) |

Eye: Safety Glasses; Respiratory: Crucial - Evaluate Dust (N95+); Hand: Suitable Gloves (Caution near nip points); Hearing: Evaluate Noise |

|

Surface Conditioning, Polishing & Buffing (Non-Woven Belts/Discs/Pads, Buffing Wheels, Compounds) |

Airborne Dust/Fibers/Compound Residue, Eye Irritation, Rotating Parts, Entanglement, Noise |

1910.94(b) (Ventilation); 1910.133 (Eye); 1910.138 (Hand); 1910.134 (Resp); 1910.95 (Hearing); 1910.212 (Guarding) |

Eye: Safety Glasses; Hand: Suitable Gloves; Respiratory: Evaluate Dust/Fumes (Ventilation Preferred); Hearing: Evaluate Noise; Body: Apron? |

|

Wire Wheels & Brushes (Cup, End, Handheld, Wheel) |

Flying Wires (High Velocity), Eye Injury, Punctures/Lacerations, Rotating Parts, Entanglement, Noise |

1910.133 (Eye); 1910.138 (Hand); 1910.95 (Hearing); 1910.212 (Guarding) |

Eye/Face: Face Shield OVER Glasses; Hand: Durable/Leather Gloves; Hearing: Evaluate Noise; Body: Leather Apron/Jacket Recommended |

|

Other Tools (Burrs, Saws, Files/Pads, Flooring Abrasives) |

Varies: Blade Contact, Chips, Cuts, Abrasion, Dust, Noise |

1910.133 (Eye); 1910.138 (Hand); 1910.134 (Resp); 1910.95 (Hearing); 1910.212/Tool Specific |

Eye: Safety Glasses; Hand: Suitable Gloves; Respiratory: Evaluate Dust (esp. Flooring); Hearing: Evaluate Noise (esp. Flooring) |

Protecting Workers While Using Abrasive Tools and Products

Safety is good business. By implementing the right PPE program, you’re not only meeting OSHA standards—you’re creating a safer, more efficient workplace. Review your current practices, close any compliance gaps, and ensure your PPE strategy is built for both protection and performance.

Compliance Reminder

This article is based on our interpretation of OSHA’s guidelines as of the date of publication. OSHA regulations are updated regularly, and specific requirements may vary depending on your operations. For the most accurate and up-to-date information, please refer directly to the official OSHA standards or speak with a representative from your regional OSHA office.

Referenced OSHA Standards

Referenced Standards, Regulations, and Guidelines

Below is a comprehensive list of every standard, regulation, and guideline mentioned in your article, including both OSHA and non-OSHA sources. Each entry includes a brief description and a direct link to the official regulation or guideline.

OSHA Standards

|

Standard/Guideline |

Description |

Link |

|

OSHA 29 CFR 1910.132 |

General requirements for personal protective equipment (PPE) in general industry, including hazard assessment, selection, use, and training. |

|

|

OSHA 29 CFR 1910.133 |

Specifies requirements for eye and face protection to protect against flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, or potentially injurious light radiation. |

|

|

OSHA 29 CFR 1910.134 |

Governs the use of respiratory protection, including when respirators are required, program administration, selection, fit testing, and maintenance. |

|

|

OSHA 29 CFR 1910.135 |

Sets requirements for head protection to guard against impact, falling or flying objects, and electrical shock and burns. |

|

|

OSHA 29 CFR 1910.136 |

Outlines requirements for foot protection against falling or rolling objects, objects piercing the sole, and electrical hazards. |

|

|

OSHA 29 CFR 1910.138 |

Requires hand protection against hazards such as cuts, abrasions, punctures, chemical burns, and harmful temperature extremes. |

|

|

OSHA 29 CFR 1910.95 |

Occupational Noise Exposure standard, requiring employers to protect workers from hazardous noise levels and implement a Hearing Conservation Program if exposures meet or exceed 85 dBA TWA. |

|

|

OSHA 29 CFR 1910.212 |

General requirements for machine guarding to protect operators and other employees from hazards such as rotating parts, flying chips, and sparks. |

|

|

OSHA 29 CFR 1910.215 |

Specific requirements for abrasive wheel machinery, including proper guarding, mounting, and maintenance. |

|

|

OSHA 29 CFR 1910.94(b) |

Ventilation requirements for polishing and buffing operations to control airborne contaminants. |

|

|

OSHA 29 CFR 1926.102 |

Eye and face protection requirements for construction industry workers exposed to hazards from flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, or potentially injurious light radiation. |

|

|

OSHA 29 CFR 1926.303 |

Safety requirements for abrasive wheels and tools in the construction industry, including guarding and use. |

Other Standards & Guidelines

|

Standard/Guideline |

Description |

Link |

|

ANSI Z87.1 |

American National Standard for Occupational and Educational Personal Eye and Face Protection Devices. Sets minimum requirements for the design, construction, testing, and use of eye and face protection devices. |

|

|

ANSI Z89.1 |

American National Standard for Industrial Head Protection. Specifies performance and testing requirements for industrial hard hats. |

|

|

NIOSH Respirator Approval |

NIOSH certifies respirators (such as N95) for occupational use. Employers must use NIOSH-approved respirators where required. |

General Guidelines Referenced

|

Standard/Guideline |

Description |

Link |

|

OSHA Hierarchy of Controls |

Framework prioritizing hazard control methods: elimination, substitution, engineering controls, administrative controls, and PPE as the last line of defense. |