Empire Abrasives Buffing Compounds

What is a Polishing (Buffing) Compound Bar?

These polishing sticks, also known as rouge bars, are made up of tightly packed abrasive materials that are held together by greasy binders. They are used to smooth out a rough surface with small scratches or surfaces that have already been sanded down, but just needs that final stage of polishing to achieve a perfect finish.

Buffing vs Polishing vs Cut Buffing vs Color Buffing

These are all processes that get you to the smoothest and brightest finishes.

Polishing is the process where you use a coarse abrasive to smooth out a surface, like using fine and finer sandpapers to smooth a piece of wood.

Buffing is a less aggressive step done after polishing where looser and finer abrasives are used to further smooth a surface with a goal of bringing out a brighter luster or a mirror finish. This is usually completed in 1-3 steps of cut buffing and color buffing.

Cut buffing is the first step in buffing a surface. This step involves using a coarser buffing compound, like black emery or brown Tripoli, to remove any scratches. Some surfaces may actually appear properly buffed at this point and not require additional color buffing.

Color buffing is the final step in gaining the maximum shine to a surface. White rouge is a very popular color buffing compound, but the “jeweler’s rouge” color compounds (green and blue) have the most fine abrasive materials that can give the ultimate shine and mirror finish on most metals, woods, stones, or plastics.

How do you use Buffing Compound Sticks/Bars?

After you have used an ultra-fine sandpaper to sand down the surface of your metal, you can get an incredibly shiny and smooth polish with the help of a buffing compound bar.

There are multiple ways to apply the abrasives from the compound bar depending on the project at hand, tools you are using, and personal preference. Common buffing tools used with polishing bars include sisal buffs, buffing drums, polishing discs/flap discs, and airway buffing wheels.

To apply the abrasive to your buffing wheel, spin the wheel on the power tool of choice and gently press the compound into the edge of the spinning polishing wheel. A small amount of the compound should transfer to the wheel.

The best advice for applying the compound bars to your polishing wheel is to apply little and often. It is also a good idea to change the wheel for each compound to avoid a mixture of abrasives building up from prior buffing rounds.

What do Different Colors of Polishing Compound Mean?

Like sanding surfaces, you’ll want to start with a higher grit abrasive and move down the line to a finer grit to get the finest polish possible. This is where the coloring of the bars comes in handy. For example, a common process is to go from black, to white, to blue for a great three-part buffing system.

The different color options of polishing bars signify the abrasive material and coarseness of the bar. The following is a quick breakdown of each polishing compound color:

Black Emery aka Black Magic

A semi-wet bar made primarily of emery, making this the coarsest buffing compound. It is mainly used removing surface imperfections and for cutting and prepping (cut buffing) materials to polish further. Black compound is recommended for starting most polishing processes. This is NOT recommended for plastics or soft metals such as gold or silver. Black buffing compound is the ideal bar for stainless steel cut buffing.

Recommended for use with: steel, stainless steel, brass, copper, cast iron, and tin plate

Pair with: sisal wheel, blue treated airway buffing wheel

Gray

An aggressive buffing compound bar that works well for a first step, cutting process for non-ferrous metals. This bar is similar in aggressiveness to the black emery bars, but formulated to work best with non-ferrous metals like aluminum, copper, and zinc to prep for color buffing by removing surface imperfections and scratches.

Recommended for use with: aluminum, zinc, copper, lead, tin, and other non-ferrous metals

Pair with: sisal buffing wheel, blue treated airway buffing wheel

Brown Tripoli

Brown Tripoli is a semi-wet compound bar made up of a coarse abrasive that is finer than the emery abrasive in black magic bars. This material provides a milder cutting action and can be used for buffing, polishing, cutting, and removing scratches.

Recommended for use with: aluminum, brass, copper, and other soft ferrous and non-ferrous metals

Pair with: blue treated airway buffing wheel, sisal buffing wheel, spiral sewn buffing wheel

White Rouge aka White Diamond Bar aka Blizzard Polishing Compound

White compound bars are the coarsest of the finishing bars (aka Jeweler's Rouge bars). This compound is great at polishing aluminum or chrome and can be used on most precious metals. It can be used as a final finishing compound for harder metals or a cutting agent for softer metals.

Recommended for use with: Ferrous and non-ferrous metals (soft and hard), plastics, aluminum

Pair with: spiral stitched or loose conventional buffing wheel, white domet flannel airway buffing wheel

Green Rouge

Green polishing compound bars are known as "high color" bars that can add a significant amount of color depth to a surface and an even brighter finish than a white diamond bar. This jeweler’s rouge is ideal for providing a high luster finish and polishing hard metals such as steel and aluminum. It is NOT recommended for wood or soft metals such as gold and silver.

Recommended for use with: Brass, copper, iron, steel, nickel, platinum, aluminum, and stainless steel

Pair with: white airway buffing wheel, spiral sewn or losse conventional buffing wheels

Blue Rouge

Blue polishing rouge is an excellent compound bar for edge finishing acrylic sheeting or restoring a clean finish on solid plastic surfaces. This bar will not remove much material, so it is best used after a surface is pre-prepped to provide a bright reflective surface.

Recommended for use with: acrylics, plastics

Pair with: untreated domet flannel buffing wheels, spiral sewn or loose muslin buffing wheel

Pink Rouge

Pink polishing compound is vegetable based and 100% animal bi-product free, making it safe for medical and food processing items. This polishing bar provides a mild cut and high coloring on acrylics and plastics that have been pre-prepped for polishing.

Recommended for use: acrylics, plastics

Pair with: untreated domet flannel buffing wheels, spiral sewn or loose muslin buffing wheel

Red Jewelers Rouge

Red polishing compound is often used by professional jewelers to bring out the highest shine polish possible on precious metals like silver and gold. This compound is a premium bar designed specifically for soft non-ferrous metals and precious metals. It is a semi-wet bar that won’t cut the metal surface.

Recommended for use: final stage polishing of soft non ferrous and precious metals

Pair with: untreated domet flannel buffing wheels, spiral sewn or loose muslin buffing wheel

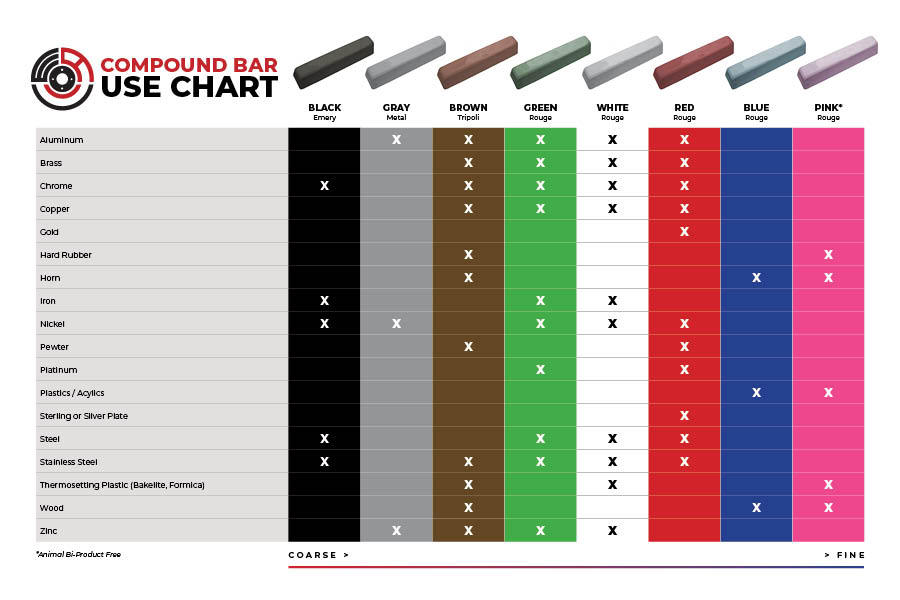

Buffing Compound Chart

See below for an easy guide to choosing the right buffing compound for your project.