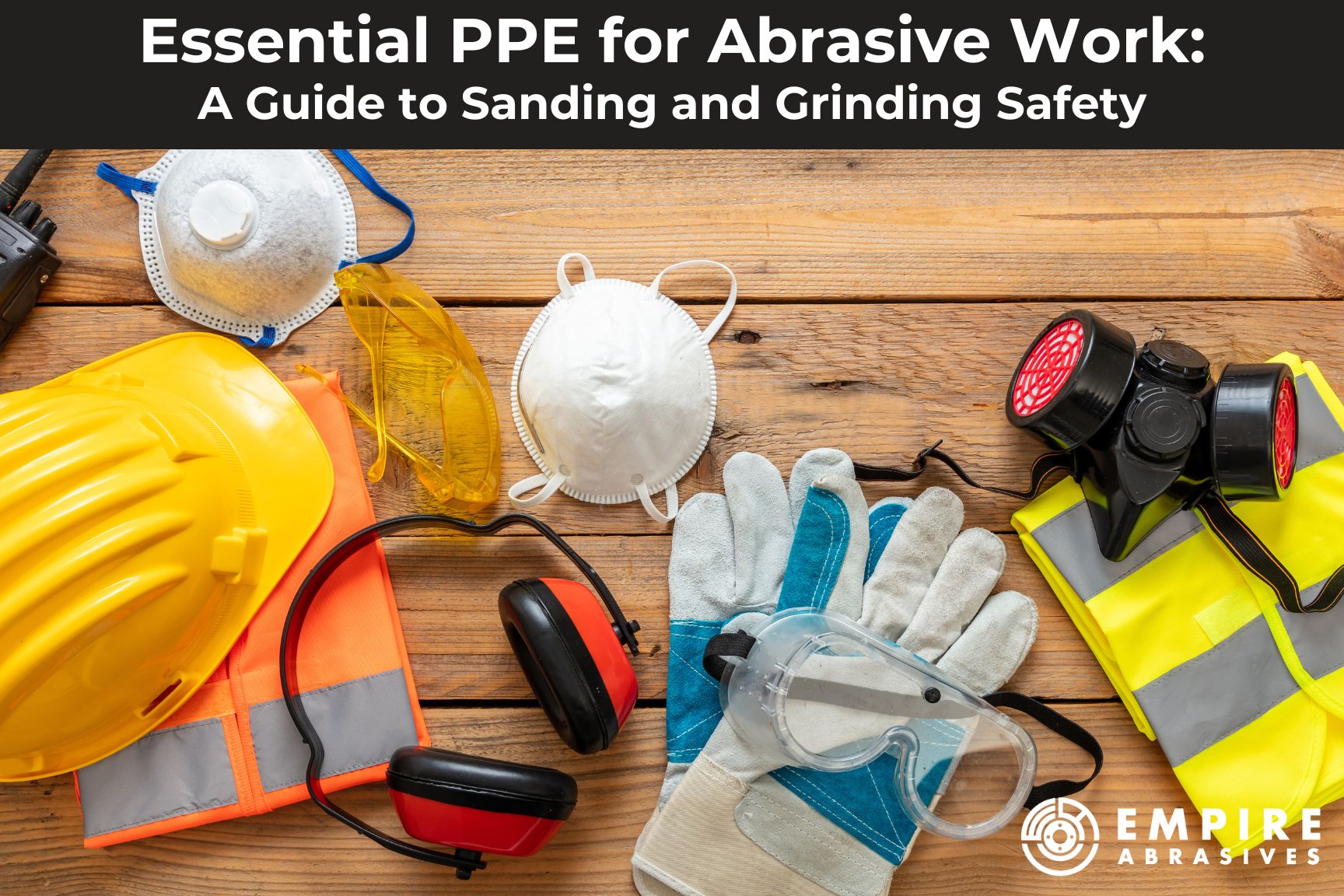

Working with abrasive tools, whether handheld or with a power tool, can be dangerous work. These jobs put you at risk for flying sparks and debris, dangerous fumes, and loud deafening noises. Before starting any task, big or small, you should always make safety your top priority, and that starts with proper personal protective equipment (PPE).

Face and Eye Protection

Flying pieces of small debris, sparks, and splintering wood are just a few of the possible hazards that abrasive use brings with them. Your eyes and face are incredibly vulnerable to these types of elements. Any of them can easily cause serious injuries or blindness.

The best way to protect your eyes is to use safety glasses or goggles that are designed for use with abrasives. These are non-negotiable when grinding or sanding anything. A strong face shield is also recommended to protect your entire face, even on top of the safety glasses.

Respiratory Protection

The dust, vapor, and fumes that float around the air when you’re grinding can cause some serious damage to your lungs. Perhaps the smallest worry you can wind up with is some slight agitation to your lungs from some sawdust. Worse than that, some materials emit toxic fumes that can poison you or cause cancer.

A simple, well-fitting, dust mask or N95 mask is a good start when working with a bit of sawdust. Respirators are non-negotiable if you're dealing with harsh fumes, toxic materials, or working prolonged jobs sanding, cutting, or grinding.

Hand and Arm Protection

When you’re working with abrasive products, your hands and arms are just inches, and sometimes almost touching the abrasive or material being grinded/sanded. The level of protection does vary depending on the task at hand, no pun intended.

Woodworking

If you’re simply hand sanding a piece of wood, some basic hand protection should be enough. Lightweight, snug fitting gloves made of materials like nitrile or latex will give you enough dexterity while also protecting you from annoying splinters. Nitrile, leather, or general-purpose work gloves with grip can be used for power sanding tools. Anti-vibration gloves can also be used to prevent discomfort, fatigue, and numbness. For your arms, long sleeves will give you some protection from flying wood chips, but avoid loose sleeves since they risk getting caught by sanding belts or power sanders.

Metalworking

Grinding metal is much riskier than wood sanding. There are chances of cutting yourself on razor sharp pieces of metal or burning yourself with sparks or hot metal fragments. You’ll have to wear more protective gloves in these situations. Reach for heavy-duty leather gloves or welding gloves when you’re grinding metal. If you’re concerned about sharp metal edges, you could benefit from wearing cut-resistant gloves with high ANSI/ISEA cut ratings (A5 and up). Arm guards are also key for avoiding injuries. For all hand and arm protective gear, make sure they are free of elements that could catch on equipment, such as loose straps or frayed edges.

Foot Protection

Crushing injuries and punctures can definitely occur with abrasive power tool use. There is always the risk of dropping heavy equipment, falling objects, and sharp debris landing on your feet. Like most work environments, you’ll want to wear sturdy steel-toed safety shoes or boots to protect your feet. It’s also a good idea to wear shoes or boots with puncture-resistant soles in case you step on a sharp object that fell off the surface you were grinding.

Hearing Protection

Abrasive tools are LOUD, even when the tools are just running. Once that grinding wheel or sanding disc touches down on a surface, the decibels jump to levels that can do permanent damage to your hearing. Earplugs or earmuffs should be worn to dampen this noise, even if you're not the one doing the grinding.

Body Protection

Protective clothing, such as aprons or coveralls, shield your body from dust, debris, and sparks. When selecting protective clothing, consider the material’s flammability and resistance to sparks to avoid a fiery disaster.

Additional Safety Measures

Beyond safety gear, we recommend considering the following when working with abrasive tools.

Proper Ventilation and Dust Collection Systems

Abrasive use generates large amounts of hazardous dust and particulates that can linger in the air. Inhaling any airborne debris can lead to serious respiratory issues and other health problems. In addition to wearing a mask or respirator, it’s a good idea to implement a ventilation and dust collection system, or at the very very least, open a window with a fan circulating the air.

Emergency Eyewash Stations

Despite wearing eye protection, there is always a chance that abrasive debris or chemicals can sneak past it and come into contact with your eyes. An emergency eyewash station is crucial for immediately flushing out any contaminants and preventing permanent eye damage. These stations should be highly visible, easily accessible, and properly maintained with fresh water/solution.

Fire Extinguishers

The sparks generated by certain abrasive processes pose a fire risk, especially when working around flammable materials or in the presence of combustible dust. Keep multiple fire extinguishers readily available throughout the work area. The extinguishers need to be labeled for the correct class for the type of fire they may need to extinguish (e.g., Class ABC for general fires, Class D for combustible metal fires). Conduct regular inspections and replace or recharge extinguishers as needed.

First Aid Kits

Even if you’re wearing all of the recommended safety gear and using your tools the right way, accidents still happen. Your jobsite or workshop should have a first aid kit ready to treat minor injuries. It should contain a variety of bandages, antiseptic wipes, pain relievers, and other necessary supplies for basic first aid.

For more safety tips on using abrasives -