Spiral bands are a specialty abrasive product designed to provide you with a high degree of precision and control with your grinding and sanding tasks. They are indispensable tools for professionals and DIYers, offering unmatched versatility for various materials and applications.

These abrasives are ideal for sanding small, delicate parts, as well as for finishing with intricate details. Spiral bands are also relatively easy to use, making them user-friendly for beginners.

What are Spiral Bands?

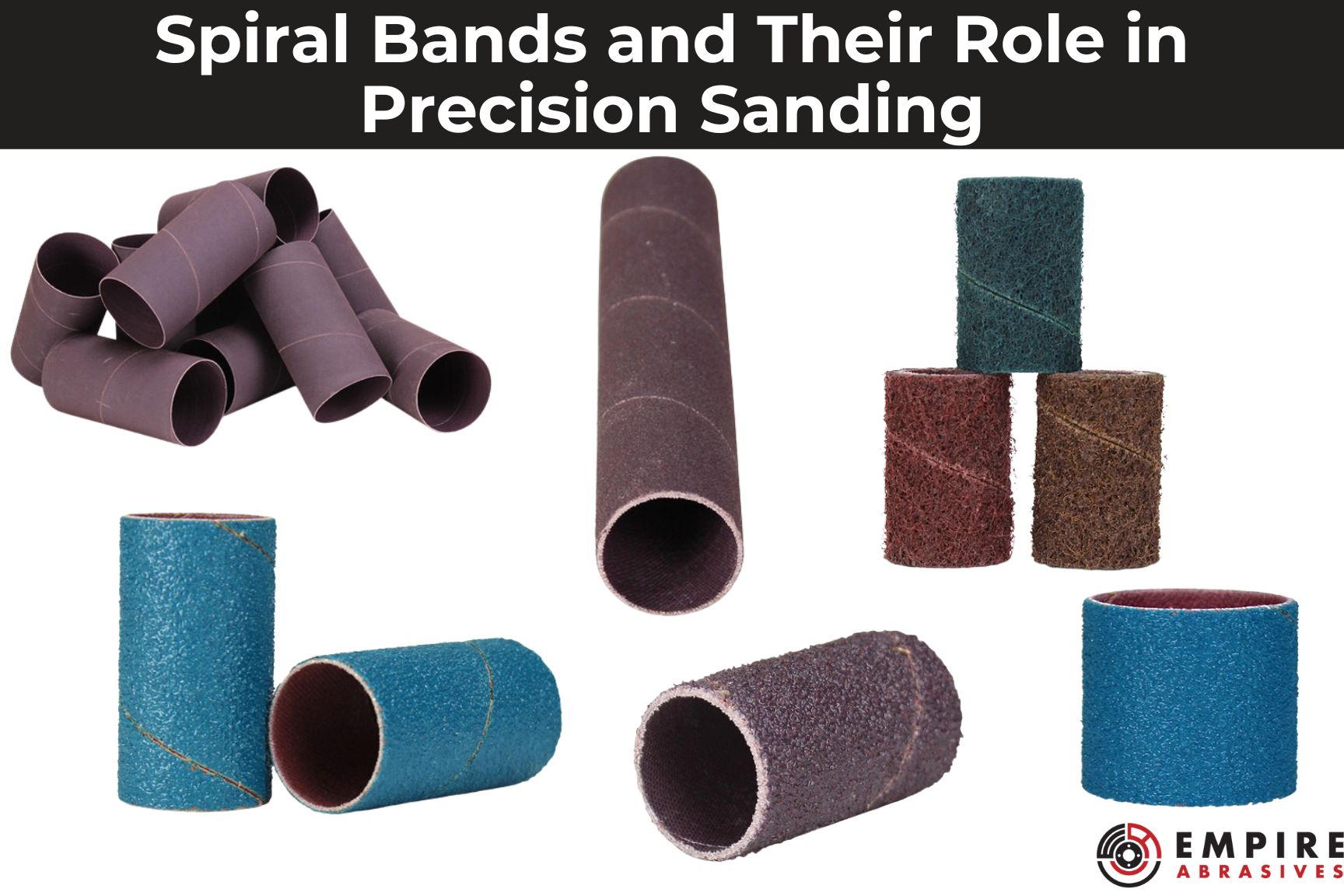

Spiral bands are small round tubes of abrasives, usually coated with either aluminum oxide or zirconia grains. They are perfect for grinding in tight areas or when working on contoured surfaces. Known also as drum rolls, these bands slide over a rubber expanding drum which attaches them to a die grinder or drill, providing flexibility and precision in finishing ornate surfaces.

Benefits of Using Spiral Bands

There are many benefits to using spiral bands, including:

- Precision: The design of spiral bands allows them to reach into tight spaces and intricate areas that other sanding tools cannot. This makes them ideal for sanding small, detailed projects.

- Versatility: Spiral bands are available in a variety of abrasive grains and grits, making them suitable for a wide range of materials and applications. They can be used to sand wood, metal, plastic, and other materials.

- Ease of Use: Spiral bands are very easy to use, even for beginners. They can be attached to a variety of sanding tools, and they are simple to operate.

- Consistent Sanding Action: The spiral pattern of spiral bands ensures that they abrade the surface of the workpiece evenly. This results in a smooth, uniform finish.

- Customizability: Spiral bands are available in a variety of sizes and shapes. This allows them to be tailored to the specific needs of a project.

Abrasive Grains for Spiral Bands and Their Uses

Spiral bands are available in a variety of materials, each with its own unique properties and uses.

Aluminum Oxide Spiral Bands

Aluminum oxide spiral bands are a versatile and affordable option that is ideal for a variety of applications. They are made from a hard, abrasive material that is effective at cutting through material quickly. Aluminum oxide spiral bands are also relatively inexpensive, making them a good choice for budget-minded users.

Aluminum oxide spiral bands are ideal for sanding, grinding, and deburring metals, wood, fiberglass, and plastic. They can also be used for sharpening tools and blades.

Zirconia Spiral Bands

Zirconia (zirc) spiral bands are more durable and longer-lasting than aluminum oxide spiral bands. They are also more aggressive, making them a good choice for heavy-duty applications. Zirconia oxide spiral bands are ideal for grinding and polishing a range of materials, from ferrous and non-ferrous metals to wood and plastic.

For more information on the difference between aluminum oxide and zirconia - Aluminum Oxide vs Zirconia Abrasives

Surface Conditioning Spiral Bands

Surface conditioning spiral bands are designed for less aggressive applications. They are made from a non-woven abrasive material that is gentler on the surface of the workpiece. Surface conditioning spiral bands are ideal for tasks like blending metal surfaces, removing paint, and rust.

Grit Range of Spiral Bands

Empire Abrasives offers spiral bands in a comprehensive grit range, from a coarse 36 grit for aggressive grinding to a fine 320 grit for final stage sanding and polishing. The different grits are ideal for a variety of applications, including:

- Coarse grit (36-60): For aggressive grinding and removal of material.

- Medium grit (80-120): For general-purpose grinding and shaping.

- Fine grit (150-220): For sanding and finishing.

- Super fine grit (320-600): For polishing and buffing.

- Non-Woven (Surface Conditioning) Spiral Bands: These bands, made from nylon webbing infused with abrasive grains, are ideal for less aggressive applications such as blending metal surfaces, removing paint, and rust. They offer a gentler approach to conditioning surfaces down to bare metal without excessive material removal.

Spiral Bands Tool Compatibility and Usage

Spiral bands are compatible with various tools, including die grinders, oscillating spindle grinders, and rotary drills. They can also be used manually for precision tasks where less aggressive sanding is required.

- Die Grinders: Ideal for precision work, die grinders work exceptionally well with spiral bands for detailed sanding tasks.

- Oscillating Spindle Grinders: These grinders offer efficient sanding for curved or contoured surfaces, making them perfect for spiral bands.

- Rotary Drills: For DIYers, rotary drills with spiral bands are great for small-scale or home projects.

- Manual Use: In situations where less aggressive sanding is needed, spiral bands can be used manually, allowing for meticulous control over the sanding process.

Expanding Rubber Drums and Spiral Bands

To use spiral bands with power tools, you need expanding rubber drums. These drums expand as the tool spins, ensuring a tight fit and stable operation.

To effectively use spiral bands with power tools, expanding rubber drums are essential. These drums play a crucial role in the functionality of spiral bands:

- Drum Design: The drums are designed to accommodate spiral bands, allowing them to slide over the drum easily.

- Operation Mechanism: When the tool spins, the rubber drum expands, creating a tight and secure fit. This expansion ensures that the spiral bands stay firmly in place, preventing slippage and ensuring consistent sanding results.

- Tool Compatibility: These expanding drums are compatible with a variety of power tools, making them a flexible option for different types of sanding projects.

Here's a step-by-step guide on how to attach them to expanding rubber drums correctly:

- Select the Right Drum Size: Match the drum size with the spiral band size for a snug fit.

- Slide the Band onto the Drum: Gently slide the spiral band over the drum.

- Ensure a Secure Fit: When the tool is activated, the drum expands, securing the band in place.

- Regular Inspection: Regularly inspect the drum for wear and tear to maintain effectiveness.

Spiral Bands vs. Cartridge Rolls

While both spiral bands and cartridge rolls are used for deburring and finishing operations, they have some key differences in design and function.

Cartridge rolls are made of layers of resin-bonded abrasives, which offer extended life and are also available in tapered shape options for more maneuverability. The tapered shape allows the cartridge roll to fit into tight spaces and reach into corners, making it ideal for deburring and finishing small parts.

Spiral bands are made of a continuous loop of abrasive material, which is wrapped around a mandrel. The spiral design allows the band to conform to the shape of the workpiece, making it ideal for deburring and finishing large or complex parts.

How to Choose the Right Spiral Band

Spiral bands are a versatile abrasive tool that can be used for a variety of tasks, from grinding to sanding. But with so many different types of spiral bands available, it can be difficult to know which one is right for the job.

Here are a few factors to consider when choosing a spiral band:

- Material: The type of material you are working on will determine the type of spiral band you need. For example, a soft material like wood will require a different abrasive material on the band than a hard material like metal.

- Desired finish: The level of finish you need will also influence the type of spiral band you choose. Finer grits are for smoother finishes, while coarser grits are for rougher finishes.

- Task: The type of task you are performing will also determine the type of spiral band you need. For aggressive grinding, you will need a coarser grit spiral band. For delicate sanding, you will need a finer grit spiral band.

- Tool compatibility: Finally, you need to make sure that the spiral band is compatible with your tool. This includes the size and the type of mandrel or drum it requires.

Example: For a wood finishing project requiring a smooth surface, opt for a fine grit (150-220) spiral band. If the task involves removing old paint from a metal surface, a coarser grit, like 60, would be more appropriate.

Here are some scenarios where you might need a spiral band and the best spiral bands for these applications:

- Scenario 1: For sanding down hardwood furniture to a smooth finish, choose a medium grit (80-120) aluminum oxide spiral band. This grit range effectively smooths the wood without being too abrasive.

- Scenario 2: When working on automotive bodywork, specifically for smoothing out filler or primer, use a fine grit (150-220) zirconia oxide spiral band to achieve a surface ready for painting.

- Scenario 3: For heavy-duty metal grinding, such as preparing steel surfaces before welding, a coarse grit (36-60) zirconia oxide spiral band is recommended for its aggressive material removal.

- Scenario 4: In detailed woodworking projects like carving or inlays, opt for a super fine grit (320-600) aluminum oxide spiral band for precision finishing without damaging the delicate wood surface.

- Scenario 5: For blending and finishing stainless steel surfaces, a non-woven surface conditioning spiral band is ideal, providing a fine, even finish without excessive abrasion or material removal.

Here are a few additional tips for choosing a spiral band:

- If you are not sure what type of spiral band you need, our abrasives experts are available to help answer any of your questions.

- Read the product labels carefully to make sure you are choosing the right grit and size.

- Start with a coarser grit spiral band and work your way up to a finer grit as needed.

- Use a sharp spiral band for best results.

- Replace the spiral band when it becomes dull or worn out.

Tips for Effective Use of Spiral Bands

Spiral bands are a versatile and effective way to sand a variety of surfaces. Here are a few tips for getting the most out of your spiral bands:

- Choose the right size and grit for your project. Spiral bands come in a variety of sizes, so it's important to choose the right one for the job. The size of the band will determine the width of the sanding area, and the grit will determine how aggressive the sanding will be.

- Ensure the bands are properly attached to the expanding drums. Spiral bands are attached to expanding drums by a series of hooks. It's important to make sure that the bands are properly attached to the drums, so that they don't come loose while you're sanding.

- Apply steady pressure for consistent sanding results. When sanding with spiral bands, it's important to apply steady pressure. This will help to ensure that the bands are making consistent contact with the surface, and that you're getting a smooth, even finish.

- Regularly check for wear and replace as necessary. Spiral bands will eventually wear out, so it's important to regularly check them for wear and tear. If you notice that the bands are starting to fray or tear, it's time to replace them.

Conclusion

Spiral bands are essential for precision sanding tasks. Selecting the right type, grit, and using them effectively can significantly enhance the quality of your work. Explore the wide range of spiral bands available atEmpire Abrasives and elevate your sanding projects to the next level.