Boost your productivity, save money on replacements, and master every finish by better understanding cloth-backed abrasives. This guide goes over everything you need to know about cloth backings, including their benefits, different types, applications, and how to select the right one for your project.

Coated Abrasives

First off, let’s talk about coated abrasives since these are the types of abrasives that you’ll find with cloth backings.

Coated abrasives are sanding and grinding products made by adhering abrasive grains to a surface like paper, cloth, etc. The “abrasive” is “coated” with grains.

Depending on the product you’re looking at, there are various ways that the abrasive grains are attached to the coating like resin bonding, electrostatic coating, or adhesives like glue.

- Resin bonding: May use multiple resin layers for enhanced strength and grain retention. Resin bonded abrasives have better resistance to heat and moisture.

- Electrostatic coating: Uses an electrostatic field to precisely position the abrasive grains on the backing. It is used to get a very even and consistent distribution of the grains.

- Glue bonding: A more traditional method where a layer of glue or other adhesive is used to adhere the abrasive grains to the backing.

- Mechanical bonding: The backing’s surface is roughened or textured with the abrasive grains interlocked with this surface.

Further reading –

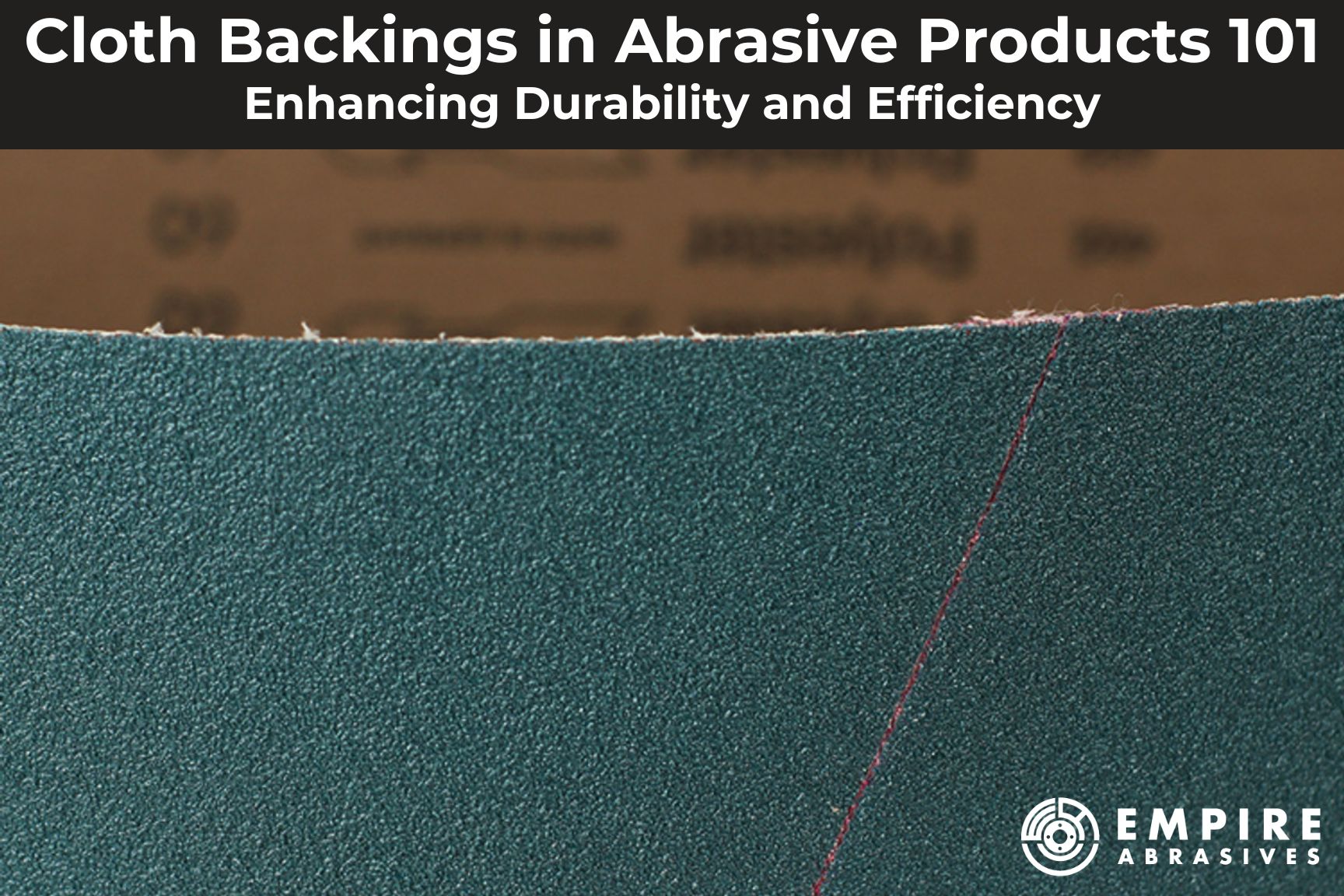

What is Cloth Backing?

When you’re shopping around for different coated abrasive products like, sanding belts and flap discs, you’ll often see that they have cloth backing. Different backings will vary among different abrasive products. The type of backing is fundamental in determining how that particular abrasive product performs.

The backing of an abrasive is basically what the abrasive grains are attached to. For example, traditional sandpaper sheets have a paper backing that abrasive grains are glued onto. The “paper” is right there in the name. Modern abrasive products are available with different types of backing, like cloth.

Different Types of Cloth

The type of cloth backing chosen directly affects how your abrasive performs. From the longevity of the product to how suitable it will be for specific tasks, the backing plays a major role in getting you the desired results efficiently and effectively.

Your choice of cloth material should be made based on the intended use of the abrasive product:

- Cotton: Known for its flexibility, cotton backing is ideal for detailed and contour work.

- Polyester: Its strength makes it suitable for tougher, more demanding jobs.

- Poly-Cotton Blends: These provide a good balance between both flexibility and strength for a wide range of applications.

Backing Weight

Another spec you’ll see with cloth-backed abrasives is the “backing weight”. The term "weight" refers to the density and thickness of the cloth material used as the backing. The weight of the cloth backing determines the strength, flexibility, and suitable applications of the abrasive.

The letters (J, X, Y, etc.) are standard industry labels that correspond to different weights and characteristics of the backing material. Here's what each letter signifies:

J-Weight:

- Meaning: 'J', sometimes referred to as jeans, is a lightweight and very flexible cloth backing.

- Characteristics: It is typically made from a lighter, more pliable material like cotton. J-weight cloth is so flexible that it can be folded or rolled without cracking or tearing.

- Uses: Ideal for applications that require the abrasive to conform to intricate shapes and contours, such as fine woodworking or detailed metalwork.

X-Weight:

- Meaning: 'X', sometimes referred to as drill, is a medium-weight and more durable cloth backing.

- Characteristics: It's sturdier than J-weight and offers a good balance between flexibility and strength. X-weight cloth is usually made from stronger materials like polyester or a blend, which can handle greater stress.

- Uses: Suitable for general-purpose sanding tasks and is commonly used to make a variety of abrasive products for both industrial and DIY applications. Most sanding belts and quality flap discs will have an x-weight backing.

Y-Weight:

- Meaning: 'Y' indicates a heavy-weight and very strong cloth backing.

- Characteristics: It's the thickest and most robust type, providing excellent durability and resistance to tearing. Y-weight backings are typically made from strong materials and are less flexible than J or X weights.

- Uses: Often used in heavy-duty industrial applications where high pressure and aggressive material removal are needed, such as metal fabrication.

Benefits of Cloth Backing

Cloth backing in abrasive products have a number of benefits that enhance their performance:

- Durability and Longevity: Cloth-backed abrasives are known for their strength and long lifespan, even in demanding conditions.

- Flexibility: They conform well to different shapes and surfaces, making them versatile for a wide range of tasks.

- Strength: The tough nature of cloth backing allows you to use it for more aggressive sanding or grinding without the risk of tearing.

- Consistency: With its strong grain adhesion, abrasive grains can wear down more evenly, leading to consistent abrasion and a uniform finish throughout its use.

- Suitability for Multiple Applications: From heavy-duty grinding to fine polishing, cloth-backed abrasives are adaptable to various tasks.

Cloth vs Other Backing Types

We’re not going to say that cloth backing is “better” than others, since each type of abrasive is made for their own use-cases. It’s important to know the different types of abrasive backing types so you can get the right one for your particular job.

Cloth vs. Paper Backing:

- Paper Backing: Generally used for lighter work and fine finishing. It's more flexible than cloth, allowing for a smoother finish on delicate surfaces. However, it's less durable and can tear easily under heavy use.

- Cloth Backing: Better for heavy-duty tasks and when you need an abrasive that can withstand repeated use or higher pressure. While less flexible than paper, it offers greater durability and tear resistance.

Cloth vs. Film Backing:

- Film Backing: Often used in applications requiring ultra-fine finishing, such as in the automotive and electronics industries. Film backings provide a more uniform finish and are more expensive than cloth. Film backed sanding discs are also usually capable of wet sanding and create less dust.

- Cloth Backing: Better suited for general to heavy-duty tasks, where durability and longevity are priorities. It is certainly capable of finishing, but film provides a superior option for ultra-fine finishes.

Cloth vs. Foam Backing:

- Foam Backing: Excellent for contour sanding and applications requiring a cushioned, flexible backing. Provides a very fine finish but is not as robust as cloth for heavy applications.

- Cloth Backing: More suitable for aggressive sanding or grinding. The foam might offer more contour flexibility, but cloth provides a blend of strength and adaptability that foam can't match in tougher scenarios.

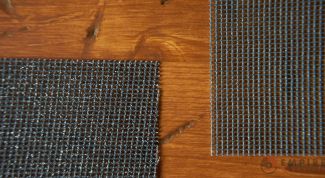

Cloth vs. Mesh Backing:

- Mesh Backing: Known for its dust extraction capabilities, mesh backing reduces clogging/loading and creates a cleaner work environment. However, it might not offer the same level of durability as cloth.

- Cloth Backing: While not as effective in dust extraction, cloth excels in strength and longevity, making it a reliable choice for more rigorous tasks.

Further reading - Types of Coated Abrasives Backing

Applications of Cloth-Backed Abrasives

Cloth-backed abrasives are incredibly versatile, used across various industries and applications. Here’s a few of the common uses where they shine:

- Metalworking: For grinding, deburring, and finishing metal surfaces. Cloth backing withstands the heat and pressure generated in metalworking and by welders.

- Woodworking: Ideal for shaping and smoothing wood, especially in furniture making and carpentry. Cloth's flexibility contours to curves and details better than stiffer backings.

- Automotive: Used extensively in auto body work for surface preparation and finishing. Cloth's durability helps when working on large areas and blending metal.

- Construction: Used across construction projects for anything from preparing and cleaning surfaces for painting, finishing, and repairs to smoothing and shaping concrete, wood, and metal in construction projects.

- Bladesmithing: Cloth-backed sanding belts for knife making are essential DIY knife making tools that offer extra control and durability that bladesmiths need to precisely grind and refine their blades to a razor-sharp finish.

- DIY Projects: Their durability and flexibility make them a favorite among DIY enthusiasts for home improvement tasks.

Selection Guide for Cloth-Backed Abrasives

Choosing the right cloth-backed abrasive is key to achieving the best results. Here’s what to consider:

Task-Based:

Your specific project will always determine the type of abrasive you need. For heavy grinding, opt for stronger backings like Y-weight. For finer, detailed work, a J-weight backing might be more suitable. For wet sanding, always check with the manufacturer to make sure the cloth is suitable for wet sanding before use.

Material

Different materials require different abrasives. Consider the material you’ll be working on and choose accordingly.

Match the abrasive grain type (like aluminum oxide or silicon carbide) with the cloth backing for optimal performance.

Bond Type

Consider whether an open-coat or closed-coat is best. Open-coats help reduce loading. Closed-coats can maximize cutting speed.

Compatibility

Choose an abrasive that is compatible with your tools’ specifications like size, thickness, arbor hole size, max RPM, and mounting type (hook & loop, PSA, etc.).

Maintenance and Safety

Proper care and safety practices are just as important when using cloth-backed abrasives as any other abrasive product. Here’s how to ensure longevity and safe usage:

- Storage: Keep them out of direct sunlight and in a cool, dry place to prevent moisture damage and warping.

- Inspection: Regularly check for tears or unsafe wear before use to avoid accidents.

- Safety Gear: Always use appropriate safety gear like gloves, eye protection, and a mask when using these or any other abrasives.

- Quality Matters: Investing in high-quality abrasives from trusted suppliers like Empire Abrasives not only ensures better performance but also enhances safety.

Remember, taking care of your tools is as important as choosing the right one.

Empire Abrasives’ Range of Cloth-Backed Products

Empire Abrasives takes pride in offering a wide range of top-quality cloth-backed products tailored for various applications. Our selection includes:

- Sanding Discs and Belts: Available in multiple grits and sizes, perfect for everything from heavy-duty grinding to fine finishing.

- High Performance Features: Our products are designed for maximum efficiency and durability, for a longer lifespan and consistent performance.

- Specialized Options: Whether you need abrasives for metalworking, woodworking, or automotive tasks, we have the right product for you.

Explore our range to find the perfect match for your specific needs.

- Sanding Belts

- Coated Abrasive Drums

- Continuous Longboard Sandpaper Rolls

- Spiral Bands

- Cross Pads

- Flap Wheels

- Sandpaper Sheets

- Flap Discs

- Hook & Loop Sanding Discs

- PSA Sanding Discs

- Quick Change Sanding Discs

- Floor Sandpaper Rolls, Discs, and Belts

Conclusion

Understanding the features and characteristics of cloth backings in abrasive products is key to selecting the right tool for your project. Their durability, flexibility, and consistent performance make them invaluable tools in various industrial and DIY applications. We at Empire Abrasives are committed to providing you with high-quality, dependable abrasives to help you achieve the best results in your work.

- Explore Our Products: Browse through our selection of cloth-backed abrasives and discover the quality that sets us apart.

- Need Assistance? If you have questions or need guidance, our team is here to help. Contact us for personalized recommendations based on your specific needs.

![Black Hawk 3 inch mini flap disc with a Roloc quick change attachment. This flap disc has a poly/cotton blend backing and zirconia abrasive grain. It is ideal for grinding and sanding on metal surfaces [Empire Abrasives] Black Hawk 3 inch mini flap disc with a Roloc quick change attachment. This flap disc has a poly/cotton blend backing and zirconia abrasive grain. It is ideal for grinding and sanding on metal surfaces [Empire Abrasives]](../../../product_images/uploaded_images/poly-cloth-backed-mini-flap-discs.jpg)