If you're in working in any industry ranging from metalworking to automotive, you'll know that tungsten carbide burrs are essential tools Known for their hardness and durability, these tools are vital in shaping, grinding, and removing material from workpieces.

However, like all tools, tungsten carbide burrs are not immune to wear and other common issues. This article will provide an overview of tungsten carbide burrs and delve into some of the frequent problems that may arise, offering practical solutions for troubleshooting and maintenance. We’ll also dive into some carbide burr maintenance suggestions and burr usage tips.

Jump Ahead

- Understanding Tungsten Carbide Burrs

- Common Carbide Burrs Issues

- Additional Tips for Using Carbide Burrs

Understanding Tungsten Carbide Burrs

Tungsten carbide burrs are rotary cutting tools made from tungsten carbide, a material known for its incredible hardness and resistance to wear. They come in various shapes and sizes and are used in die grinders, rotary tools, or automated machinery to cut, shape, or smooth materials such as metals, plastics, and ceramics.

These burrs offer precision and efficiency, enabling you to perform intricate tasks and heavy-duty applications. The benefits of tungsten carbide burrs are particularly apparent in industries where high-speed, precision cutting is required, and they have become an indispensable tool for professionals and DIY enthusiasts alike.

Common Carbide Burrs Issues

Like any tool you might use, problems can occur with tungsten carbide burrs. Recognizing and addressing these problems early can save time and money, ensuring that the burrs continue to function at their best. If you're looking to expand your collection or replace worn-out burrs, consider checking out sets of carbide burrs for a comprehensive range of options.

Here's a closer look at the specific challenges that might arise.

Burr Wear

When you use these tools, you'll notice that burr wear will happen eventually after enough use. However, excessive or uneven wear can indicate underlying problems. Here's how to recognize and address burr wear:

Symptoms of Wear

Look for a loss of sharpness, uneven edges, visible reduction in the burr's size, or discoloration or change in the burr's appearance

Causes of Wear

Wear can result from using the burr at incorrect speeds, applying excessive pressure, using it on inappropriate materials, exposure to corrosive materials, or using the burr continuously without giving it time to cool down. Sometimes, the wear results from the tool's natural depletion over time.

Troubleshooting Burr Wear:

- Ensure the burr gets used at the correct speed according to the manufacturer's guidelines.

- Inspect the burr regularly for signs of wear and replace it when necessary.

- Compare the burr's performance with a new one to gauge wear.

Preventing Future Wear:

- Implement regular maintenance checks.

- Apply consistent, moderate pressure to avoid overloading the tool.

- Follow proper usage guidelines.

- Rotate between multiple burrs to distribute wear evenly.

- Make sure the burr is compatible with the material you are working on.

- Select the right quality tungsten carbide burrs, such as those offered by Empire Abrasives.

For regular tasks, double cut carbide burrs with a 1/4" shank are a popular choice due to their versatility.

Inefficient Cutting

Have you ever noticed inefficient cutting by your tungsten carbide burrs? This can lead to poor results, and extended work time, impacting productivity and quality.

Symptoms of Inefficient Cutting

Some symptoms can be slower cutting speed, Excessive material residue on the workpiece, increased effort required, and uneven or rough finish.

Causes of Inefficient Cutting

This issue can be due to dull burrs, improper tool selection, incorrect operating speed, or a mismatch between the burr and the material.

Troubleshooting Inefficient Cutting:

- Inspect the burr for wear and replace it if needed.

- Test the burr on a sample material before the main workpiece.

- Adjust the operating speed according to the manufacturer's recommendations.

Preventing Future Inefficient Cutting:

- Regularly clean and maintain the burr to prevent material buildup

- Choose the appropriate burr for the material and task.

- Use high-quality tungsten carbide burrs like those from Empire Abrasives.

Burr Breakage

Burr breakage is a serious problem that can halt operations and lead to injury.

Symptoms of Burr Breakage

A sudden snap or break in the tool, or earlier signs being visible cracks or fractures on the burr.

Causes of Burr Breakage

Common causes include excessive force, dropping the tool, using the wrong burr type, or a manufacturing defect.

Troubleshooting Burr Breakage:

- Assess the situation for safety concerns.

- Determine the cause of the breakage and replace the broken tool.

Preventing Future Breakage:

- Use the correct burr type.

- Ensure proper storage conditions.

- Handle the tool with care.

- Opt for quality brands like Black Hawk Abrasives that undergo rigorous quality checks.

Overheating

Overheating can cause discomfort during use and negatively impact the tool’s lifespan.

Symptoms of Overheating

Excessive heat during operation, unusual smell while cutting, or discoloration of the burr or workpiece.

Causes of Overheating

Overheating often occurs due to excessive pressure, high speed, or continuous use without allowing the tool to rest.

Troubleshooting Overheating

- Allow the tool to cool down.

- Adjust speed and pressure to recommended levels.

Preventing Future Overheating:

- Follow proper operating guidelines.

- Take regular breaks during extended use.

- Consider using cooling options like a coolant or lubricant.

- Work in a well-ventilated area to help disperse heat more effectively.

Excessive Noise or Vibration

Ever been bothered by noise or vibration while working with burr bits? It can lead to discomfort and even affect safety.

Symptoms of Noise or Vibration

Unusual sound or feel during operation.

Causes of Excessive Noise or Vibration

Typically, imbalanced tools, worn-out parts, misalignment of the burr in the tool, or incorrect usage cause this problem.

Troubleshooting Noise or Vibration:

- Inspect the tool for balance and wear.

- Adjust usage to follow the manufacturer's guidelines.

- Re-fit the burr and ensure its properly aligned.

- Ensure that the workpiece is securely clamped or held in place.

Preventing Future Noise or Vibration:

- Regular maintenance checks

- Correct handling of the tool while cutting/grinding.

- Regularly check the tool's fitting mechanism.

Inconsistent Finishes

Inconsistent finishes can result in an unprofessional appearance and may require additional work to correct, wasting time and resources.

Symptoms of Inconsistent Finishes

Some symptoms can include uneven texture, varying glossiness, or irregular patterns like swirl marks on the finished surface.

Causes of Inconsistent Finishes

This could be due to using worn or damaged burrs, inconsistent pressure or speed, or a mismatch between the burr and the material being worked on.

Troubleshooting Inconsistent Finishes

- Check the burr for damage and replace it if necessary.

- Ensure that the tool gets used at a consistent speed and pressure.

- Use consistent hand movements.

Preventing Future Inconsistent Finishes:

- Regular inspection and maintenance of the burr.

- Practice on sample materials to perfect your technique.

- Properly handle of the tool during operation.

- Use the correct tungsten carbide burrs suitable for the specific task.

Rapid Dulling

Have your burrs dulled out faster than expected? Rapid dulling can lead to inefficient cutting and the need for frequent replacements.

Symptoms of Rapid Dulling

There are several symptoms of rapid dulling that can be present. These symptoms include decreased cutting efficiency, increased friction during operation, or the burr appearing blunt or worn.

Causes of Rapid Dulling

Excessive pressure, using the burr on inappropriate materials, or using poor-quality burrs can lead to rapid dulling. Check for these causes before troubleshooting.

Troubleshooting Rapid Dulling

- Replace the dulled burr with a new one.

- Assess the usage method and material compatibility.

Preventing Future Rapid Dulling:

- Select the appropriate burr for the specific job.

- Follow proper usage guidelines during operation.

- Use high-quality tungsten carbide burrs, such as those from Empire Abrasives.

Material Smearing

If you've noticed a sticky or smeared appearance on your workpiece, it might be due to material smearing. Material smearing alters the surface appearance and can cause additional problems in further processing.

Symptoms of Material Smearing

The main symptom of material smearing includes a sticky or smeared appearance on the burr or the surface being worked on.

Causes of Material Smearing

Smearing can occur due to too much heat, using a dull or incorrect burr, or incorrect speed.

Troubleshooting Material Smearing

- Clean the affected surface.

- Check and replace the burr if needed.

- Adjust speed and pressure as per recommendations.

Preventing Future Material Smearing:

- Use the correct type of burr for the material being worked on.

- Maintain proper operating speed and pressure.

- Use intermittent cuts to prevent excessive heat build-up.

- Conduct periodic checks for wear and tear on the burr to ensure it's in optimal condition.

These common issues with tungsten carbide burrs can be efficiently managed with proper understanding, attention to detail, and following best practices in their usage. Investing in quality tools from trusted sources like Empire Abrasives and adhering to proper maintenance routines will ensure that your abrasive tools remain in peak condition, delivering the best results for your projects.

Additional Tips for Using Carbide Burrs

Tungsten carbide burrs are versatile tools used across various industries. Here are some additional tips to enhance their efficiency and longevity:

- Select the Right Burr for the Job: When selecting the right burr for the job, consider the shape that best suits your needs. Whether it's a cylinder, ball, cone, or other shapes, each has its unique advantages. Remember to also choose the right shank size, either 1/4 inch or 1/8 inch, and the type of cut, be it double cut or aluma cut.

- Follow Manufacturer Guidelines: Refer to the guidelines provided by the manufacturer for optimal speed, pressure, and handling. This information is often vital for preventing common issues.

- Regular Maintenance: Regular cleaning and inspection of the burr can prevent unexpected wear or breakage. Make it a habit to inspect the burr before each use.

- Avoid Overheating: Use cutting fluids if recommended, and allow the burr to cool down if you detect excessive heat. Overheating can cause many of the issues discussed earlier.

- Invest in Quality Tools: Quality matters. Choosing products from reliable sources like Empire Abrasives ensures you work with tools designed to meet industry standards.

- Safe Handling: Proper safety protocols, including protective gear, should always be followed. Safety should be a priority in all operations.

- Environmental Considerations: Proper disposal of worn-out burrs and consideration of environmental factors are also essential. Follow local regulations for disposal and recycling.

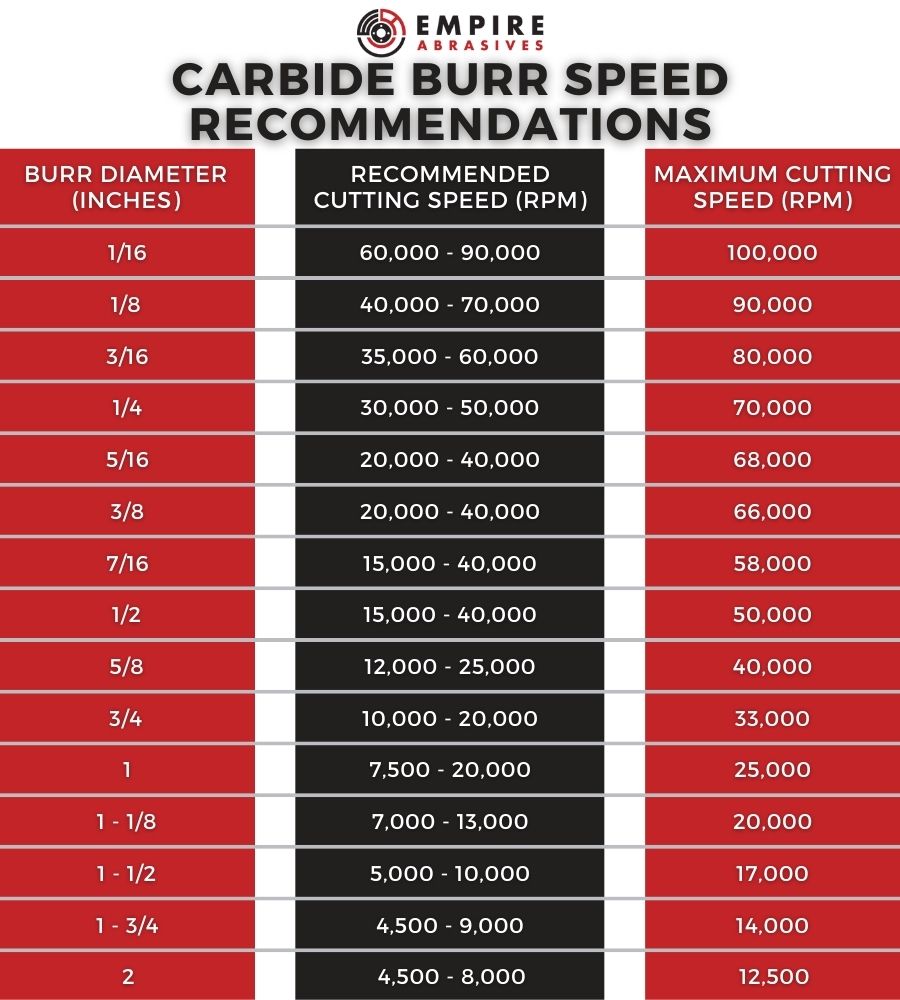

Below are some recommendations for burr speeds based on the burr diameter:

Conclusion

For many like you, tungsten carbide burrs are indispensable tools. But as with all specialized equipment, they require understanding and care. By identifying and addressing common issues such as burr wear, inefficient cutting, burr breakage, overheating, excessive noise or vibration, inconsistent finishes, rapid dulling, and material smearing, you can can enhance the efficiency and lifespan of your carbide burrs.

The actionable tips and insights reinforce trust in Empire Abrasives as a leading source of quality abrasive tools and knowledge. Whether you are a professional or a DIY enthusiast, following these guidelines ensures that you are well-equipped to effectively handle and maintain your tungsten carbide burrs, leading to superior project outcomes.

Need Some Replacement Burrs?

Shop with Empire Abrasives today and experience lightning-fast shipping. Place your order, and it'll be in the mail within one business day. Have questions? Our dedicated customer service team is here to assist you during office hours via phone, email, or online chat. If you miss us, just leave a voicemail or email, and we'll get back to you the very next business day.

More from our abrasives troubleshooting series:

- Troubleshooting Common Abrasive Tool Issues - Sanding Belts

- Troubleshooting Common Abrasive Tool Issues - Cut-Off Wheels

- Troubleshooting Common Abrasive Tool Issues - Grinding Wheels for Angle Grinders

- Troubleshooting Common Abrasive Tool Issues - Wire Brushes

- Troubleshooting Common Abrasive Tool Issues - Flap Discs