There are a lot of different abrasive grain types and each job may require different abrasive material. We’ve posted an article in the past about some of the different abrasives, mainly comparing ceramic vs zirconia abrasives, but we’d like to discuss these red colored ceramic abrasives at more length for you.

This particular abrasive grain is the newest material created for the abrasive industry. Ceramic alumina is not found in nature. It is what you call an artificial or manufactured abrasive since it’s been created through man-made/scientific means. Through this innovation, ceramics have been found to be a superior abrasive for many applications.

Key Takeaways

- Ceramic abrasives use micro-crystalline structures that self-sharpen.

- They cut faster, last longer, and generate less heat than traditional abrasives.

- Best suited for stainless steel, titanium, and heavy-duty applications.

- Zirconia and aluminum oxide remain better budget-friendly options for softer metals.

- Higher upfront cost = lower cost per grind in demanding environments.

What is a Manufactured/Artificial Abrasive?

This isn’t that important to know when buying ceramic abrasives, but we’re including this information for those of you interested in the nitty-gritty scientific details of how things are made.

Natural abrasives like garnet and emery are found in nature, hence the "natural" abrasives name. Artificial abrasives were created scientifically through different processed, creating all new materials that have qualities that natural products aren’t capable of. So then, how is ceramic alumina made?

The process of making ceramic abrasives involves a chemical procedure of creating a colloidal solution, sol, that contains tiny particles of aluminum oxide in a liquid medium. For an easy visual, think of mud. Dry mud is just tiny pieces of dirt, but mixed with water it becomes a liquid-like structure that still contains all of those tiny dirt pieces.

The sol-gel process is what forms many metal oxides such as silicon, titanium, and ceramic alumina. For ceramic alumina, bits aluminum oxide alloy is suspended in the sol mixture. As it dries under controlled temperature, the minerals will separate from the binding agent.

The final step is called sintering, which is another heat treatment that causes the aluminum oxide powder grains, or crystals, to shrink and become denser and stronger. During this process, individual crystals combine to create a polycrystalline material with larger grit sizes.

How Tough are Ceramics?

Ceramic abrasives are some of the strongest and sharpest abrasives currently on the market.

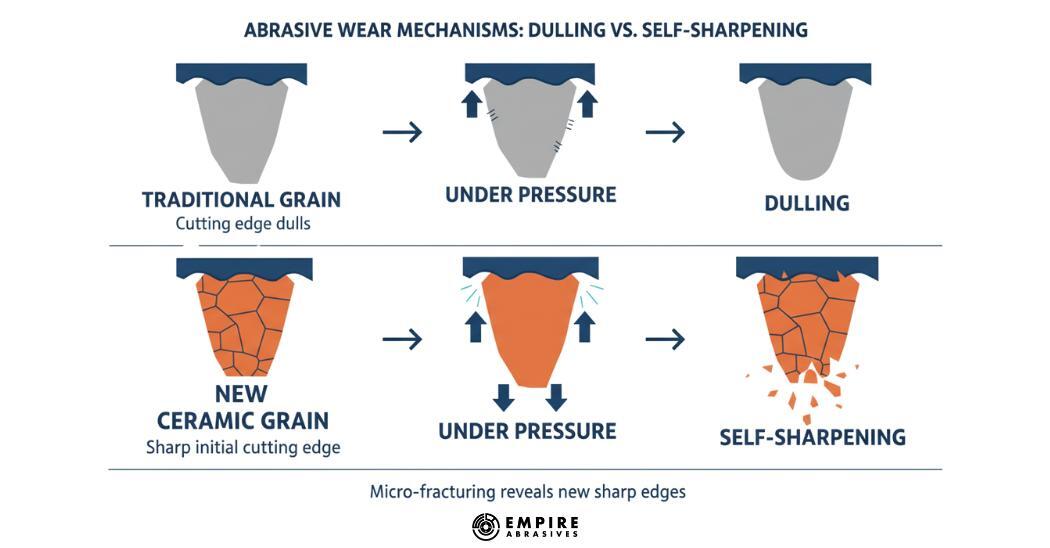

Ceramics are a friable abrasive, meaning that as the product is being used, tiny pieces of the grit will fracture off exposing fresh sharp material. This helps the ceramic abrasives constantly renew the surface to provide a consistent cutting and grinding action for a longer period of time.

Ceramic sandpaper and other abrasives are strong enough to cut and grind most metal surfaces such as carbon steel, aerospace alloys, titanium alloy, aluminum, ferrous metals, and nonferrous metals.

When you use it on superalloys and stainless steel it will perform better than most other abrasives. Ceramic will not dull as quickly due to its extreme toughness and self-sharpening abilities. That level of toughness will allow ceramic abrasives to provide outstanding grinding and finishing performance on a variety of different hard metals.

How can you Use Ceramic?

Ceramic abrasives have become a favorite among knifemakers, auto body workers, and metal fabricators. It is commonly used in aerospace applications as well as blasting, blending, burnishing, cleaning, surface preparation, and abrasive jet cutting to name a few.

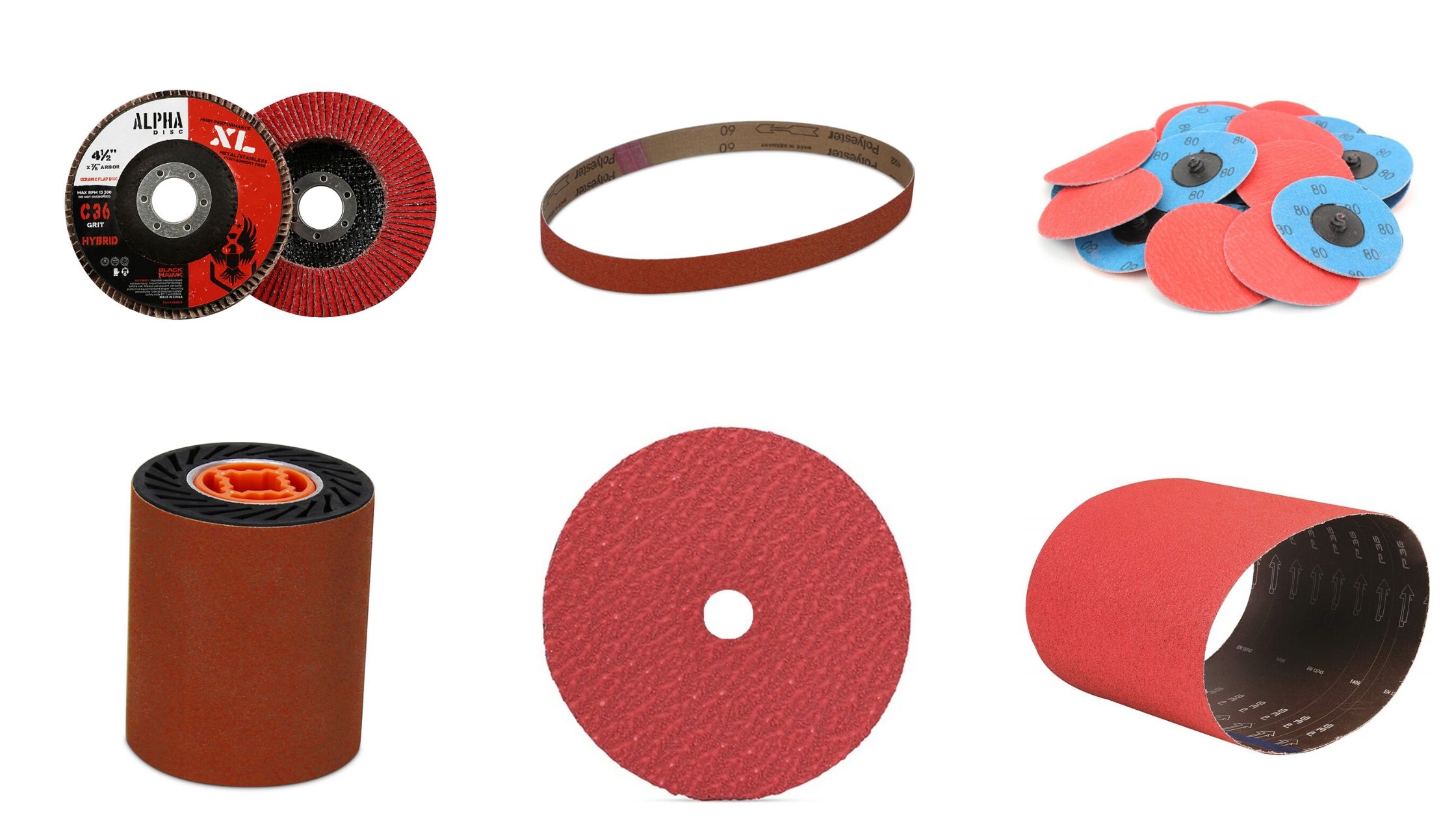

Depending on the task at hand and the tool you prefer, there is a wide variety of ceramic aluminum oxide abrasive choices. Ceramics are available in products like the Black Hawk Abrasives 2’ Quick Change Ceramic Disc for those hard to reach corners to even 12" Ceramic PSA Sanding Dics. As ceramic becomes more common in the market it is easy to find things like 6” x 48” Ceramic Sanding belt, which has become one of our top selling belts in ceramics as more customers branch out into testing other grains. If you want to see all our options and sizes in ceramic sanding belts please do!

Can I Use Ceramic Abrasives on Wood?

The short answer is yes, but...

It is best used on wood when you need rapid wood removal as it will not develop smooth surfaces. It is only good for roughing out and quick material removal. A lot of our customers who use wood as their medium use our ceramic sanding discs in the 8” model with the cloth backing. You will not see the ceramic perform to the best of its abilities when used on wood.

Wood is also not hard enough to allow the ceramic to renew and resharpen its grains. Wood itself is not hard enough to allow you to take advantage of the life-extending friability feature of these abrasives.

Can I Use Ceramic Belts for Knife Making?

Absolutely! Ceramics have been slowly being adopted and used in many trades and is growing to be a favorite among bladesmiths as they can get so much use out of one ceramic belt as it lasts so much longer than both aluminum oxide and zirconia and can handle exotic metals. We have a wide selection depending on your personal knifemaking tools setup, but our 1” x 30” ceramic belts and 2” x 42” sanding belts are very popular in the knife maker community.

What Else Should I Know About Using Ceramics?

Abrasive ceramics are best used to grind and cut away other softer material. It’s hardness and resistance to wear are unparalleled. That hardness is considered to be necessary so that the abrasive does not shatter during the grinding process. The grain self-renews with micro-fractures. As you use the abrasive, it will break down into smaller razor-sharp pieces multiple times over before it finally dulls.

Although ceramic can be used for roughing out wood, it does perform best on hard metals. They are commonly used in deburring, deflashing, descaling, stripping, fast cutting, intermediate cutting, aggressive material removal, grinding, and ball milling to name a few.

Benefits of Ceramic Abrasives

Long-lasting - can last up to 6x longer than other abrasive grain types

Friable abrasive - self-sharpening to continue working with consistent grinding and cutting

Low-pressure application - does not require the operator to exert as much pressure as other abrasives due to unique sharpness and hardness of the grains

Low temperature - generates much lower heat than the majority of the alternatives.

Is the Cost of Ceramic Worth It?

The cost of ceramic is generally at least 50% higher than most other abrasive grains. However, it will deliver between two and four times the performance over aluminum oxide or zirconia. When you are deciding on which abrasive is right for it is important to separate the price and the cost. The price may be higher with ceramic abrasives, but the total cost of the job (product + time + labor) will be substantially less.

Another factor to consider is the long life of the ceramic abrasives. They generally last up to 6 times longer than their alternatives, meaning you won’t need to buy replacements nearly as often.

What Grits do Ceramic Abrasives Come In?

Ceramic, like zirconia, comes in the coarser grits from as low as 24 to as high as 120. Ceramic is meant, as mentioned earlier, to remove the softer material and is only available in the coarser grains.

What Types of Products Can I Get Ceramic In?

As ceramic is being adopted more and more as a superior abrasive by more people, it is being implement in more abrasive products. Ceramic can be found in pressure-sensitive adhesive discs (PSA), quick change discs, sanding belts in a variety of sizes, resin fiber discs, and ceramic flap discs. We are continually adding more ceramic-based abrasives to our line of products to keep up with all of our customers’ needs.

Ceramic Abrasives FAQ

Q: What is the main advantage of ceramic abrasives? A: The main advantage is their self-sharpening ability. The micro-crystalline grains fracture under pressure, constantly exposing new, sharp cutting edges. This results in a longer lifespan, a faster cut rate, and less heat buildup.

Q: Which is better, ceramic or zirconia flap discs? A: For heavy-duty grinding on heat-sensitive metals like stainless steel, ceramic is better due to its longer life and cooler cutting. For general-purpose steel grinding where cost is a factor, zirconia offers excellent performance.

Q: What materials are ceramic abrasives best for? A: Stainless steel, high-alloy steels, titanium, and hardened metals benefit most from ceramics.

Q: How do ceramic abrasives compare to aluminum oxide? A: Ceramic lasts up to 4–6 times longer and cuts more aggressively than aluminum oxide, especially on tough metals.

Q: Do ceramic abrasives cost more? A: Yes, but their longer lifespan and efficiency often lower cost per use compared to cheaper abrasives.

Q: Why do ceramic abrasives stay sharper? A: They are engineered to self-sharpen by fracturing at a microscopic level under pressure.

Q: Is ceramic good for grinding stainless steel? A: Yes, ceramic is the best choice for stainless steel. It cuts cooler than other abrasives, which helps to prevent heat discoloration (bluing) and warping of the stainless steel workpiece.

Q: What is a grinding aid? A: A grinding aid is a chemical top-coat applied to some abrasives, especially ceramic, that acts as a lubricant. It reduces heat and friction during grinding, which prevents loading and prolongs the life of the abrasive.

Glossary

- Ceramic Abrasive – Engineered abrasive with micro-crystalline structure that self-sharpens.

- Zirconia Abrasive – Tough, long-lasting abrasive ideal for medium-duty grinding.

- Aluminum Oxide – Common, inexpensive abrasive for wood and softer metals.

- Friability: The ability of an abrasive grain to fracture and break down under pressure, creating new sharp edges. This is the key to a "self-sharpening" abrasive

- Grinding Aid: A top-coat lubricant applied to abrasive grains that reduces friction and heat during grinding, preventing the workpiece from burning and the abrasive from loading.

- Loading: When the gaps between abrasive grains become clogged with sanding residue, which reduces the abrasive's cutting ability.

Quick Recap

- Choose Ceramic for: High-performance grinding on heat-sensitive and hard metals like stainless steel, titanium, and exotic alloys. Best when longevity and cut rate are top priorities.

- Choose Zirconia for: A versatile, all-around performer on steel and stainless steel. Offers a great balance of durability, speed, and cost for most metalworking applications.

- Choose Aluminum Oxide for: General-purpose sanding on softer materials. The most economical choice for wood, plastics, aluminum, and carbon steel.

Additional Resources:

- Ceramic vs. Zirconia Abrasives: Which is the best option?

- Cut, Grind, and Sand Cooler: How to Choose the Right Abrasives

- Understanding Friability in Abrasives: What It Is and Why It Matters

- Abrasive Hardness, Toughness, and Friability Made Simple

Still Don’t Know if you Should Use Ceramic Abrasives?

If you are unsure if ceramics are right for you, please do not hesitate to reach out to us. We know how difficult it can be when a few products may work for you and we’re here to help guide you as best we can. Please feel free to reach out to one of our experts at Empire Abrasives, 1-800-816-3824. Whether you are experienced or a novice -- we are always happy to lend a helping hand.

Last Updated: 9/4/25