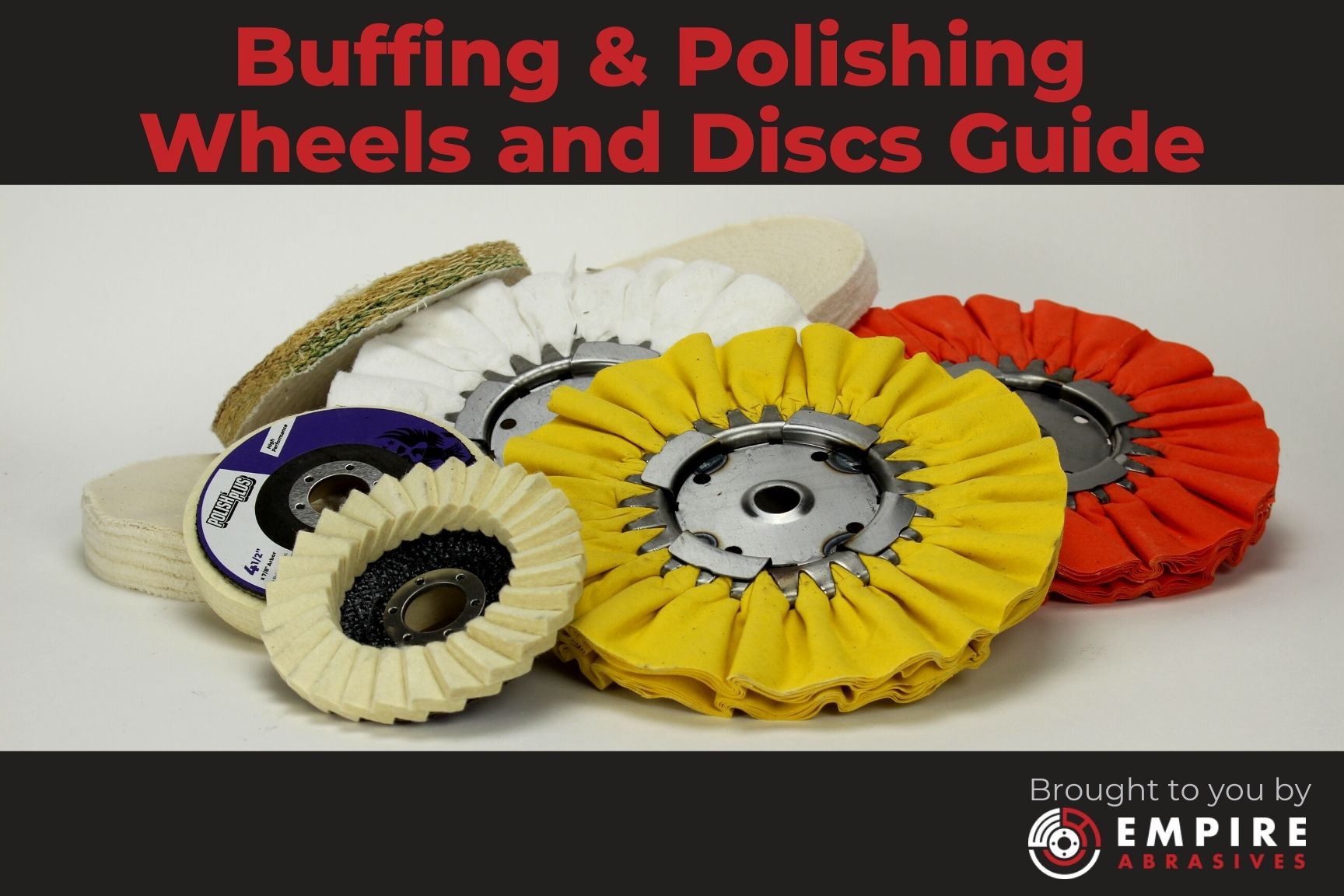

When you take a look at all of the different options for buffing and polishing products, it’s easy to get a little lost in what is the best tool for what you need at a given time. Each of these tools has different uses and benefits that you should consider before tackling your buffing job. We’d like to help clear things up by comparing the different types buffing and polishing attachments for various power tools you might come across.

Key Takeaways/TLDR:

- Polishing is for surface correction. It uses abrasives to remove scratches, oxidation, and other flaws, creating a smooth, uniform surface.

- Buffing is for shine and finish. It uses a finer abrasive compound and a wheel to create a high-gloss, reflective, mirror-like finish.

- It's a two-step process. You must polish a surface before you can effectively buff it. Buffing a rough, unpolished surface will only highlight its imperfections.

- Tools are different. Polishing often involves discs, pads, or belts. Buffing is almost always done with a cloth-like wheel paired with a fine compound.

- Use the right compound for the metal (tripoli/white diamond/rouge/emery) and dedicate wheels to one compound

Airway Buffing Wheels

At EmpireAbrasives.com, we sell 3 styles of 8” Airway buffing wheels. They are all made with a 3” center plate and a ⅝” arbor hole. They have been designed to be used on an angle grinder, bench top lathe, polisher/sanding machine, variable speed polisher, and more.

Each of these buffing wheels are 16-ply, meaning 16 cotton layers are attached to the center plate. They are attached in a special way that creates pleats throughout the entire wheel. These pleats allow for extra airflow during buffing and allows the buffing wheel to run at cooler temperatures protecting the airway buffs from overheating, which can extend the product's life as well as the workpiece.

The main difference you’ll see between each airway buff is the color treatments. Each color signifies a different level of hardness for each wheel. The hardness/stiffness of the airway buffs should be considered for which step of the buffing and polishing process you’re on, as well as what metal you are working with.

Orange Mill Treated - These are the firmest airway buffs. The stiffness of the orange airway buffing wheels allows them to both cut and color aggressively. These generally work best for the beginning stages of buffing, often using black magic or brown tripoli buffing compound.

Yellow Mill Treated - Yellow treated wheels are 15% less stiff than the orange mill treated. While you can use the yellow mill treated airway buff for both color and cutting, it is ideally suited for color with light cutting. You will likely get the best results from this colored airway buff when using green rouge buffing compound.

Untreated White Domet Flannel - White airway buffs are the softest and most delicate of our three airway buffs. The white flannel is an ultra plush option for getting an ultra high luster and perfect mirror finish. Unlike the treated counterparts, there is no noticeable stiffness.

The airway buffs are designed for you to use the edge of the buffing wheel for the actual polishing, while evenly applying buffing compound bars as the cutting agent. This method is called edge buffing and is commonly used when polishing metal with a buffing wheel or an angle grinder.

This buffing wheel must be used with a specific ventilated flange as to prevent delamination from the steel center. We also recommend always raking your buffing wheels between uses. This will help to prevent compound build up and remove any hardened and burned-on compound from the edges of your wheel. This will help extend the life of your airway buff and help you get more consistent results.

Sisal Buffing Wheels

At EmpireAbrasives.com, we also carry sisal buffing wheels, another buffing and polishing wheel known for their aggressive cutting capabilities. Sisal buffing wheels are made from cellular fibers formed into a thin cord that the buffing wheel is constructed from. These fibers are known for their high strength foundation in creating binders’ twine, cords, ropes, etc. They are naturally abrasive, and the cellular fibers are also grease absorbing.

Our sisal buffing wheels are all closely stitched with a ¼” stitch spacing and spiral sewn. The hardness of the buff is within the spacing of the stitching. The ¼” stitching is the most popular especially when you want a hard buff.

These buffing wheels will provide both polishing and cutting action. Sisal buffs are often the first buffing wheel used for cutting processes, especially for harder metals like stainless steel or iron. They will also remove things such as: stretcher stains, polishing wheel grit lines, light die marks, orange peel, etc. They are most commonly used for finishing roll formed, drawn, and stamped metals. When combined with cloth, they can cut and finish stampings in a single operation prior to preplating.

It also runs cooler due to the airflow from the center of the buff. Sisal buffing wheels have been designed to be used with a bench grinder, bench polisher, bench top lathe, or buffing machine.

When using a sisal wheel it is common to have to add more buffing compound in short intervals such as every 30 to 60 seconds. If using the sisal wheel in combination with the black compound does not take out your scratches then you will need to do further sanding on your workpiece.

In order to extend the life of the wheels and avoid accumulating hardening compounds, it is recommended that you rake your sisal buffing wheels.

Conventional Buffing Wheels

Muslin cotton style buffing wheels are made of high quality, soft muslin cotton. They can come in sewn 20-ply and a loose 60-ply. Muslin cotton is very similar to cotton flannel buffing wheels. The higher the ply count is then the thicker the buffing wheel will be. You can get these buffing wheels as small as 4” and as large as 10” from EmpireAbrasives.com

Spiral Sewn Muslin Buffing Wheels

These are typically one of the most popular wheels chosen for buffing and polishing work. The plies of the cotton muslin cloth are sewn together spirally with ¼” spacing. The tighter spiral sewing allows the wheel to become harder/denser and thus more pressure can be applied to it.

This is commonly used for cutting metal as the spiral sewn muslin buffing wheels excel at both cutting and coarse buffing. They also excel at cutting down more fragile workpiece materials. Each spiral stitched buff is crafted from premium muslin woven cotton cloth that contains between 64-68 threads per inch! The cloth layers are then stitched together from the center and sewn in a circular spiral pattern up to the outer edge of the buff. These have been designed to be used with a bench grinder, bench polisher, lathe, or a drill with a proper mandrel.

Pro Tip - As you use a spiral sewn muslin buff, the edges will wear away, getting closer to the stitching. You can cut away and remove the outermost stitching to use the wheel longer. Removing the stitching also makes the wheel less dense and can be taken out if you need a softer buffing surface. Simply cut the string and pull out the threading.

Loose Cotton Muslin Buffing Wheels

Loose cotton buffs are used with polishing compounds and are perfect for the final finishing work. These buffing wheels come in 60-ply and are unstitched like the spiral-sewn alternative, but are sewn once around the arbor hole. The edge of these buffs are soft and feel almost felt-like.

Because of the softness of these wheels, they conform to the workpiece you are polishing as you apply pressure. This makes them the perfect solution for curves, contouring, and any other awkward angles/crevices much more easily than their sewn counter parts. They also naturally generate less heat than their stitched counterpart.

The loose cotton muslin buffing wheels are also excellent for light cutting and coloring on nearly all metals and plastics.

Like the spiral sewn, they are designed to be used with a bench grinder, bench polisher, lathe, or a drill with a proper mandrel.

Felt Polishing Discs

Felt polishing discs and wheels are crafted from tightly compressed, high-quality Australian wool. The felt polishing discs are medium hardness and are used for all-purpose buffing and polishing with various polishing pastes or buffing compounds. They are versatile and can be used with any compound for both polishing and cutting. They retain their edge, and are excellent for angles and corners.

Black Hawk Abrasives Polish Plus felt discs have been specially designed to offer flexibility to polish on contoured surfaces while providing a cooler working action to prevent burning on the workpiece of discoloration. They are available in the 4.5” x ⅞” Flap Disc, 4.5” x ⅞” Flat Disc, 2” Quick Change, and the 3” Quick Change.

The polishing flap discs work great with angle grinders. Whereas the quick change polishing discs are versatile and with the backing pad can be used in die grinders, drills, and air grinders.

Buffing Drums

Buffing drums are specially made for the final stages of both buffing and polishing on different metals and some wood surfaces. The drums have a much larger surface area than other polishing tools with a wide 4” wide working surface. That allows the operator to cover a lot of surface space and cut down on the time spent buffing and polishing for large projects such as: RV’s and airstreams, full vehicles, and large metal fabrication prep work. EmpireAbrasives.com’s selection of buffing drums have a hub that fits a ¾” keyed shaft and were created to be used on surface finishing machines and linear grinding machines such as: burnishers, burnishing machines, contouring grinders, and surface conditioning tools.

Spiral Sewn Buffing Drum

Black Hawk Abrasives’ spiral sewn polishing drums are made of soft premium muslin cotton sheets that have been stitched together in a spiral pattern that starts from the center of the drum and sewn circularly to the outer edge of the buffing drum.

These drums are to be used with a buffing compound and are specially designed for the first step in cutting, coloring, and polishing surfaces. Due to the size and design they are able to cover larger areas much more quickly than a standard polishing disc. They are a favorite buffing tool among many auto body workers and metal fabricators since they can help polish large jobs in less time than standard buffing wheels.

Flap Buffing Drum

Black Hawk Abrasives’ flap buffing drum is a great last step for polishing and buffing larger workpieces. They have been designed to work well on both flat and curved surfaces. This gives the operator the ability to create a perfect mirror finish on various different materials. The continuous rotation of the drums combined with the one-way pulling motion allows the operator to avoid buffing swirls when using the flap buffing drum unlike when using polishing wheels that spin and often create these swirl patterns.

The premium felt wool flaps have been positioned radially and fan out from the drums center. This design will allow air flow through the flaps and reduce heat on both the drum and the workpiece. Like all polishing wheels, each drum should be dedicated to one polishing compound and be reused with that compound only. A buff rake to get the hardened pieces off.

FAQ - Buffing & Polishing Wheels and Discs Differences

Q: Can you buff without polishing first? A: It's not recommended. Buffing is a finishing process designed to create shine. If you try to buff a surface that still has scratches and flaws, the buffing process will only make those imperfections more noticeable by shining them.

Q: What is the main difference between a buffing wheel and a polishing pad? A: A polishing pad is typically flatter and uses abrasives to remove material and correct surface flaws. A buffing wheel is softer, made of cloth-like materials, and is used with a fine compound to produce a high-gloss, reflective shine.

Q: What are the different colors of buffing compound for? A: The colors indicate the compound's abrasive level and intended use. Generally, it progresses from black (coarsest, for cutting) to brown, white, and blue (finer, for polishing), and finally to red (rouge, finest for jewelry) and green (for stainless steel).

Q: How do I choose the right buffing wheel? A: Choose based on the task. Use firm, spiral-sewn wheels for aggressive "cut" buffing to remove fine scratches. Use softer, loose or canton flannel wheels with a fine compound for the final "color" buffing to achieve a mirror finish.

Q: Do I need different wheels for different compounds? A: Yes. dedicate each wheel to a single compound to avoid cross-contamination and streaking.

Q: Can polishing remove deep scratches? A: Polishing can remove fine to moderate scratches and surface haze. Deep scratches or gouges that you can catch a fingernail on usually require a more aggressive first step, like sanding, before you can begin polishing.

Q: What is a "rake" used for with buffing wheels? A: A buffing wheel rake is a tool with sharp steel teeth used to clean the wheel's surface. It removes dried-on compound and metal particles, exposing fresh fibers and preventing a loaded wheel from scratching your workpiece.

Q: What does “spiral-sewn” vs “loose” muslin mean? A: Spiral-sewn wheels are denser and cut more; loose wheels are softer, conform better to curves, and are used for final coloring.

Q: What are sisal wheels good for? A: Aggressive first steps on hard metals (e.g., stainless) to remove lines and heavy marks before switching to muslin/flannel.

Mini-Glossary

- Abrasive: A substance, such as grit or a compound, used for grinding, polishing, or cleaning a hard surface.

- Buffing: A finishing process that uses a soft wheel and a very fine abrasive compound to create a high-gloss, mirror-like surface.

- Compound: A paste-like or solid bar material, typically made of fine abrasive particles mixed with a grease or wax binder, that is applied to a buffing wheel.

- Cut Buffing: The initial, more aggressive stage of buffing that removes very fine surface scratches left over from polishing.

- Color Buffing: The final, less aggressive stage of buffing that produces the highest level of gloss and shine.

- Polishing: A finishing process that uses an abrasive on a wheel, disc, or pad to remove surface imperfections like scratches, oxidation, and tool marks.

- Rouge: An extremely fine polishing compound used as the final step in producing a mirror finish, especially on precious metals.

- Rake: Cleaning a buff to remove hardened compound build-up and keep it cutting evenly.

Additional Resources:

- What's the Difference: Buffing vs Polishing

- Metal Buffing Tips for Professional Finishes

- Choosing the Right Buffing Products for a Mirror Finish on Metal (DIY Guide)

- How to Buff and Polish Copper

- How to Buff and Polish Brass

- How to Buff & Polish Stainless Steel

- How to Polish Aluminum

- What is Sisal (Material)?

Quick Recap

- Polishing = fixed abrasive leveling; buffing = soft wheel + compound for luster

- Pick airway for cooler work on big surfaces; muslin (spiral-sewn → loose) as you move from cut to color.

- Sisal first for hard metals/heavy marks; finish with muslin/compound.

- Felt discs reach edges/angles on handheld tools.

- Match compound to metal (tripoli/white diamond/red rouge/black emery)

Still Don’t Know Which Buffing Wheel is Best for Your Project?

If you are still unsure which one is right for you, please do not hesitate to reach out to us. We know how difficult it can be when a few products may work for you and we’re here to help guide you as best we can. Please feel free to reach out to one of our experts at Empire Abrasives, 1-800-816-3824. Whether you are experienced or a novice -- we are always happy to lend a helping hand.

Last Update: 9/4/25